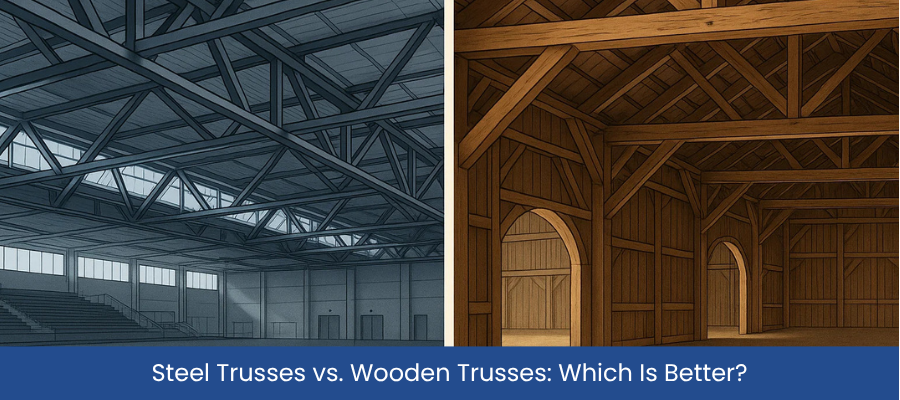

Steel Trusses vs. Wooden Trusses: Which Is Better for Large Structures?

Strength and Load-Bearing Capacity

One of the most important factors in selecting trusses for large structures is their strength and ability to support significant loads. Steel trusses provide superior strength compared to wooden trusses, making them ideal for applications that require heavy load-bearing capacity.

- Steel Trusses: Steel is a material known for its high tensile strength. Steel trusses can handle much higher loads without bending, warping or failing. This makes them perfect for large spans where large machinery or heavy materials need to be supported. The ability of steel to resist bending under pressure ensures the overall safety and stability of large structures.

- Wooden Trusses: Wooden trusses, while strong in their own right, fall short in comparison. Wood has a lower strength-to-weight ratio and its capacity to carry heavy loads is limited. In large structures, wooden trusses often require additional support to bear heavy loads, leading to additional costs and more complex designs.

Durability and Longevity

Durability is a key consideration, particularly when building structures that are meant to stand the test of time. Whether dealing with harsh weather conditions or the natural wear and tear from heavy use, the material’s resilience plays a significant role in long-term performance.

- Steel Trusses: Steel is incredibly durable. It resists rust, decay, rot and the damage caused by environmental factors like moisture, pests or temperature fluctuations. Unlike wood, steel does not suffer from termites, mold or mildew, which can degrade wooden structures over time. Steel trusses have a longer lifespan and require minimal maintenance, making them an investment that pays off over decades.

- Wooden Trusses: Wood is much more vulnerable to environmental degradation. It can rot when exposed to moisture, warp under extreme heat or humidity and can be susceptible to pests such as termites and carpenter ants. As a result, wooden trusses often require regular inspections, treatments and replacements, which increases both maintenance costs and downtime.

Cost and Maintenance

When considering a large construction project, cost is always a major factor. This includes both the initial cost of materials as well as long-term maintenance expenses. While wooden trusses may appear less expensive at first glance, their total cost over time may outweigh the initial savings.

- Steel Trusses: The upfront cost of steel trusses may be higher due to the price of materials and fabrication. However, steel trusses are cost-effective in the long term due to their minimal maintenance requirements and longer lifespan. The durability of steel reduces the need for repairs and replacements, saving money in the future. Furthermore, steel’s ability to span longer distances without additional support beams reduces material costs and overall construction expenses.

- Wooden Trusses: Although wooden trusses tend to have a lower initial cost, their long-term expenses can accumulate quickly. Wooden trusses are more susceptible to damage, requiring more frequent maintenance and repairs. The need for treatments to prevent decay or pest damage adds to the overall cost. Additionally, wooden trusses may need to be replaced or reinforced over time, leading to higher long-term costs.

Design Flexibility and Span Capacity

The flexibility of a material in design plays a key role, especially for large structures where the span and layout need to be adapted to specific requirements. This is where steel trusses excel.

- Steel Trusses: Steel trusses allow for greater design flexibility and the ability to create large open spaces without the need for numerous support columns. Steel’s high strength-to-weight ratio means that it can span larger distances without compromising on stability. This is particularly beneficial in the construction of large facilities such as warehouses, stadiums or manufacturing plants, where open, unobstructed spaces are essential.

- Wooden Trusses: Wooden trusses are limited in the distance they can span due to the natural properties of wood. For larger spans, wooden trusses either require additional supports or cannot handle the load without additional reinforcement. This can result in a more complicated design process, potentially adding to the construction time and cost.

Speed of Construction

In large construction projects, time is often of the essence. How quickly the structure can be built affects the overall project timeline and can impact business operations or the use of the space.

- Steel Trusses: Steel trusses are prefabricated off-site and are ready for quick assembly once delivered to the construction site. This greatly speeds up the construction process, as steel trusses can be assembled much faster than wooden trusses, which require on-site construction and adjustments.

- Wooden Trusses: Wooden trusses are often constructed and assembled on-site, which takes more time. Moreover, the need for frequent adjustments and treatments during the construction process can add significant delays, especially in large structures where numerous trusses are required.

Resistance to Environmental Factors

Large structures are often subjected to various environmental conditions, including humidity, temperature fluctuations, fire risks and pest infestations. Steel trusses provide robust protection against these elements, which makes them particularly well-suited for large-scale projects.

- Steel Trusses: Steel is inherently resistant to fire, moisture, extreme temperatures and pests. It does not corrode under typical environmental conditions when treated correctly and it is not vulnerable to termites or other pests that can damage wooden structures. Steel trusses also provide greater stability in high winds and seismic conditions, making them an ideal choice for regions prone to natural disasters.

- Wooden Trusses: Wood is more vulnerable to environmental stress. High humidity can cause wood to swell and warp, while exposure to rain or moisture can lead to rot. Additionally, wood is highly susceptible to termite infestations, which can weaken the structure. In areas with high fire risks, wood also presents a major safety concern, as it is flammable and can compromise the safety of the entire building.

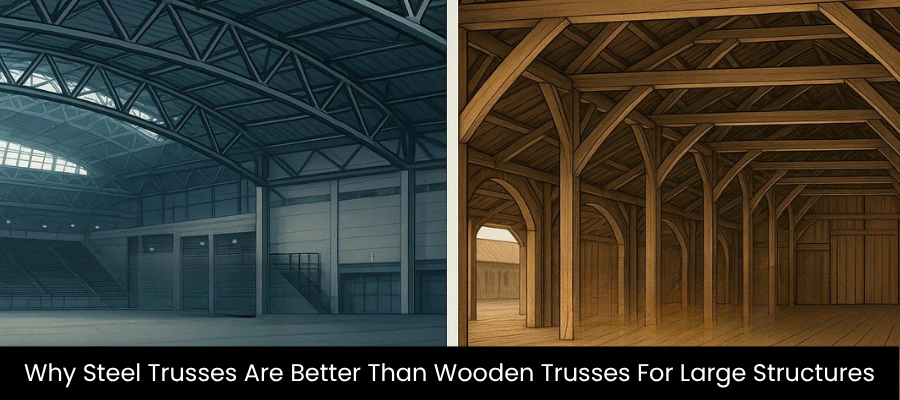

Conclusion

In large-scale construction projects, the choice of trusses has a significant impact on the strength, durability and overall performance of the structure. Steel trusses offer clear advantages over wooden trusses in nearly every category. From their exceptional strength and load-bearing capacity to their long-term cost-effectiveness and resistance to environmental factors, steel trusses are the better choice for large, heavy-duty structures.

While wooden trusses may be suitable for smaller buildings, they simply cannot match the performance of steel in larger, more complex projects. Steel trusses provide enhanced design flexibility, faster construction times and reduced maintenance, making them the ideal choice for anyone looking to build a safe, durable and cost-efficient large structure.

FAQs About Steel Trusses vs Wooden trusses

Steel trusses are stronger, more durable and resistant to environmental factors such as moisture, fire and pests. They can support larger spans and heavier loads without the need for additional supports.

Steel trusses require less maintenance due to their resistance to rot, pests and weather damage. They have a longer lifespan and do not need regular treatments or repairs, reducing long-term costs.

Yes, steel trusses are highly customizable and can be fabricated to suit various structural designs and span lengths. This makes them ideal for large, complex construction projects.

While the initial cost of steel trusses may be higher, they offer significant long-term savings due to their durability, low maintenance and longer lifespan.

Steel trusses are highly resistant to extreme weather conditions, including high winds, rain, snow and temperature fluctuations. They provide superior protection against environmental factors compared to wooden trusses.

Founder & CEO

Mukesh Patel is the Founder & CEO of Build Matt ltd, specializing in Pre-Engineered Buildings (PEB) and general steel fabrication. With advanced technology, modern machinery, and a skilled workforce, he delivers efficient and high-quality solutions across East and Central Africa, including Uganda, Kenya, Tanzania, Congo, South Sudan, Rwanda, and Burundi.

- Steel Walkways by Build Matt Engineering the Path to Safety

- Roof Ventilation: Everything Homeowners Need to Know

- Steel Mezzanine Floors in Uganda: Comprehensive Guide by Build Matt Ltd

- Steel Trusses and Rafters in Uganda: Engineering the Future

- Steel Staircase Fabrication: A Step-by-Step Engineering Manual