CNC Plasma Cut Decorative Metal Panels

Architectural Precision for Walls, Ceilings, Partitions & More

In the world of modern architecture and interior design, visual storytelling through

material detailing has become essential. At Build Matt, we bring your spaces to life through

precision CNC sheet cutting services, specializing in decorative metal panels for a wide range

of applications — from accent walls and ceilings to functional partitions and façades.

Whether you're an interior designer aiming for a statement backdrop or a builder enhancing façade aesthetics, our CNC-cut metal panels deliver the perfect combination of art, accuracy, and durability.

Why CNC Plasma Cut Metal Panels?

Decorative panels are no longer just ornamental — they’re an extension of design intent. And CNC cutting gives you the ability to:

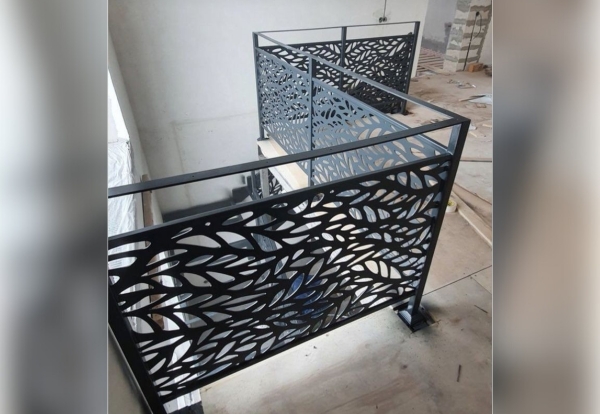

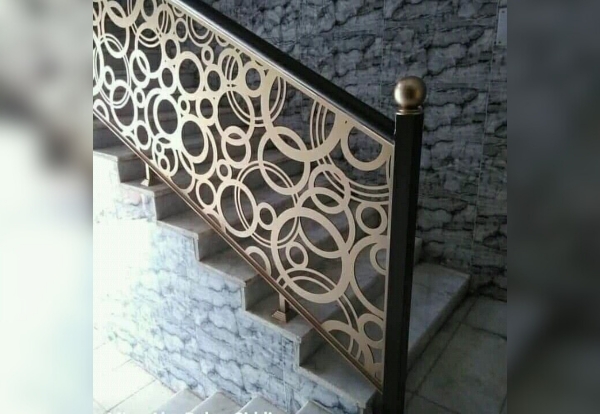

Build Matt’s CNC systems are capable of cutting floral, geometric, tribal, and abstract patterns with incredible precision. We bring together state-of-the-art machinery, design software compatibility, and local fabrication support — giving your designs a tangible and timely form.

Decorative Metal Panels We Fabricate

We design and cut custom decorative panels for a wide range of design applications. Every panel is tailored to your pattern, dimensions, material, and finish preferences.

Wall Cladding Panels

Transform bare walls into design features with precision-cut panels in MS, aluminium, or SS. Suitable for:

Ceiling Panels & Lighting Screens

Introduce depth, light diffusion, and acoustic relief with our laser-cut ceiling panels. Designed for:

Custom Artworks, Murals & Signage

Whether it's your brand logo or a tribal motif, we cut it clean:

Partition Screens & Room Dividers

Create functional segmentation while retaining openness and elegance. CNC-cut partitions are perfect for:

Facade & Exterior Panels

Enhance your building’s identity with metal façade elements cut to perfection. Ideal for:

All panels are delivered flat-packed or pre-assembled, based on your site requirements and installation method.

Materials We Work With

Build Matt supports a wide variety of metals and thicknesses to suit your functional and aesthetic goals.

| Material | Applications |

|---|---|

| Mild Steel (MS) | Cost-effective, paint-ready, good for interior/exterior walls |

| Galvanized Steel (GI) | Corrosion-resistant, ideal for partition frames and ceilings |

| Stainless Steel (SS 304/316) | Premium finish, suitable for hygiene-critical or aesthetic zones |

| Aluminium | Lightweight and rust-resistant, perfect for facades and indoor panels |

| Corten Steel | Rustic, weathered finish for exterior or garden panels |

| Brass (on request) | Elegant metallic tones for luxury spaces or signage |

Sheet thickness: 1 mm – 6 mm (varies by material and design complexity)

Each project includes material consultation to ensure the right balance between durability, budget, and design vision.

Design Capabilities – From Idea to Precision Cut

We turn your sketches, CAD layouts, or mood board inspiration into cut-ready panel files. Build Matt supports:

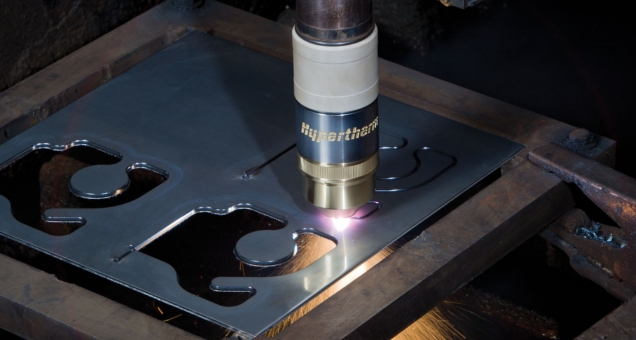

All panels are precision cut using CNC plasma or laser cutters, followed by de-burring and edge treatment, ensuring each unit is safe to handle and ready to finish.

Finishing & Coating – Where Art Meets Endurance

A great cut deserves a flawless finish. That’s why at Build Matt, we offer a full range of surface finishing and coating options to elevate the final look of your decorative panels — while protecting them from wear, corrosion, and environmental exposure.

Powder Coating

Epoxy or PU Paint Finishes

Rustic / Patina Coatings (Corten Steel, Brass)

Anodizing (for Aluminium Panels)

Brushed / Mirror Finish (for Stainless Steel)

Each panel is treated with care — cleaned, smoothed, and cured as per international coating standards. Where applicable, UV-resistant and weather-protective layers are added to ensure longevity, especially for exterior applications.

Why Choose Build Matt for CNC Decorative Panels?

Choosing Build Matt means working with a team that brings together precision technology, architectural vision, and manufacturing discipline. Our decorative CNC panel services are built around:

Architectural Precision, Every Time

We understand that every millimeter matters in architectural finishes. Our CNC machines deliver consistent, repeatable output across large batches — whether you need one panel or a hundred.

In-House Design Collaboration

Don’t have a ready CAD file? No problem. Our design team can help you:

We turn design ideas into cut-ready files and ensure they meet the application’s spatial and aesthetic goals.

Material Versatility & Stock Readiness

Our facility stocks a wide variety of metals in standard thicknesses, allowing us to turn around projects faster — and with material selection support for strength, finish, and budget alignment.

Local Support, East Africa Reach

We are proud to be based in Uganda with a growing footprint across East Africa. Our logistics team supports:

Whether you’re a builder, designer, hotelier, or retail brand, Build Matt offers collaborative engagement from concept to completion.

CNC Sheet Cutting for Perforated & Laser-Cut Panels by Build Matt Uganda:

At Build Matt, we are proud to offer CNC sheet cutting services for perforated and laser-cut panels to businesses and organizations in Uganda and surrounding countries. As specialists in metal fabrication, our services are designed to meet the exacting standards of industries ranging from construction and architecture to automotive and engineering.

With state-of-the-art CNC technology, we are able to provide our clients with high-precision panels, delivering intricate designs and superior finishes. Whether you're looking to create decorative panels for architectural facades, functional perforated panels for ventilation, or custom laser-cut designs for unique projects, Build Matt ensures exceptional quality, durability, and design flexibility.

Our CNC cutting process allows us to work with various metals, including mild steel, stainless steel, and aluminum, producing perforated and laser-cut panels that meet both aesthetic and functional requirements. We cater to custom orders, ensuring that each panel is cut to your exact specifications.

In this product page, you’ll find everything you need to know about how CNC sheet cutting for perforated and laser-cut panels can help elevate your project, how Build Matt stands out from the competition, and why our services are the perfect solution for your needs.

Why Choose CNC Sheet Cutting for Perforated & Laser-Cut Panels?

Decorative panels are no longer just ornamental — they’re an extension of design intent. And CNC cutting gives you the ability to:

Precision and Accuracy

One of the key reasons to opt for CNC sheet cutting is the unmatched precision it offers. Unlike traditional manual methods, CNC machines follow computer-generated instructions to produce cuts with extreme accuracy. This is especially important when working with perforated panels or intricate laser-cut designs that require consistency and flawless execution.

CNC technology allows for repeatable accuracy, ensuring that every batch of panels, whether small or large, maintains uniform quality. Whether your project calls for decorative perforations, functional cutouts, or exquisite detailing, CNC cutting delivers perfect results every time.

Customization and Flexibility

At Build Matt, we understand that every project is unique. That’s why we offer custom CNC sheet cutting services that allow you to tailor your perforated panels and laser-cut designs to your exact requirements. We provide the flexibility to produce panels in any shape, size, or design, including custom hole patterns, shapes, or logos.

From small decorative accents to large-scale industrial panels, Build Matt ensures that your designs are realized with precision and professionalism.

Cost Efficiency

CNC sheet cutting offers cost-effective solutions for businesses looking for high-quality perforated and laser-cut panels. Build Matt utilizes advanced CNC cutting machines that not only minimize material waste but also speed up production, offering competitive pricing for both small and large orders.

By opting for CNC cutting, companies can get high-quality panels at affordable prices, without compromising on precision or durability.

Applications Across Various Industries

Our CNC sheet cutting services cater to a wide range of applications across industries:

Whatever your needs, Build Matt offers solutions that meet the demands of your industry.

How Build Matt's CNC Sheet Cutting for Perforated & Laser-Cut Panels Works

At Build Matt, we ensure a smooth, hassle-free process from design to delivery. Here’s how our CNC sheet cutting for perforated and laser-cut panels works:

Design Consultation

We begin by understanding your project requirements. You can submit your design files in DXF, DWG, or AI formats, or our design team can help you create the perfect design.

Material Selection

Choose from a variety of materials, including mild steel, stainless steel, and aluminum, based on your project needs (whether for indoor, outdoor, or corrosion-resistant applications).

CNC Cutting

We use CNC plasma cutting, laser cutting, or waterjet cutting technologies to produce precise cuts and intricate designs with minimal material wastage.

Quality Control

After cutting, each panel undergoes rigorous quality checks to ensure dimensional accuracy, design integrity, and functional performance.

Surface Finishing

For added durability, we offer powder coating, epoxy coatings, or galvanizing based on your specifications.

Delivery

Once your panels are ready, we ensure timely delivery across Uganda and surrounding countries, making sure they arrive in perfect condition and on schedule.

Why Choose Build Matt for CNC Sheet Cutting Services?

Our Expertise

Frequently Asked Questions (FAQs) About Steel Panels

Absolutely. We provide in-house powder coating, epoxy/PU painting, and anodizing, depending on material and application.

For standard projects, lead time ranges from 5 to 10 working days after design approval. Larger or complex patterns may require additional time.

Yes. We use corrosion-resistant materials and coatings for outdoor use, including galvanization, PU paint, and weather-rated powder coats.

Yes. We supply pre-drilled panels, fastener kits, and framing accessories. For Kampala-based projects, we can coordinate on-site support.

We accept both small and large orders — from a single feature panel to bulk partitions for hotels or offices.

We offer CNC cutting services for a range of materials, including mild steel, stainless steel, aluminum, and other custom alloys, depending on your project needs.

You can submit your design files in DXF, DWG, or AI formats. Alternatively, our design team can help you create a custom design based on your specifications.

Most orders are completed within 3 to 5 weeks. For larger projects or custom designs, delivery times may vary.

Yes, we can handle both small and large-scale orders. Our CNC cutting technology ensures consistency across all orders, no matter the quantity.

We serve a wide range of industries, including architecture, engineering, construction, automotive, manufacturing, and interior design.

Whether you’re in construction, engineering, or interior design, Build Misatt Uganda’s CNC sheet cutting services for perforated and laser-cut panels offer the precision, customization, and affordability you need to bring your vision to life. With our state-of-the-art technology, expert team, and commitment to quality, we are your trusted partner for all your CNC cutting needs in Uganda and surrounding countries.

Prefabricated & Pre-Engineered Buildings

Prefabricated & Pre-Engineered Buildings

Steel Fabrication Solutions

Steel Fabrication Solutions

CNC Plasma Cutting

CNC Plasma Cutting

Steel Furniture & Custom Fabrications

Steel Furniture & Custom Fabrications

Specialized Steel & Storage Solutions

Specialized Steel & Storage Solutions

Additional Steel Products

Additional Steel Products