Cold Storage Prefabricated & Pre-Engineered Buildings

Advanced Cold Storage Infrastructure - Engineered for Precision Cooling

With two decades of specialized experience in industrial construction, Build Matt delivers technically superior Cold Storage Facilities utilizing Prefabricated and Pre-Engineered Building (PEB) systems. Our engineered solutions are tailored to meet the stringent demands of industries requiring controlled environments - such as food processing, pharmaceuticals, and cold chain logistics - where thermal stability, operational hygiene, and structural durability are non-negotiable.

Our design philosophy is grounded in a deep understanding that, in cold storage environments, thermal consistency is critical to product integrity. Each structure is meticulously developed with thermally-efficient envelope systems, precision-sealed enclosures, and custom load-bearing steel frameworks. We engineer for performance within temperature bands ranging from +20°C to -40°C, ensuring full compatibility with industrial refrigeration systems.

The Technical Edge: Prefabrication and PEB for Cold Storage

Unlike traditional masonry or RCC-based construction, which often suffers from on-site variability, extended timelines, and suboptimal thermal performance, Build Matt adopts a controlled manufacturing and modular installation approach. This not only reduces construction timelines by up to 50%, but also enhances structural accuracy, thermal retention, and site cleanliness.

Our cold storage solutions offer the following engineered advantages:

With Build Matt, every structural component - from panel joint design to steel bracing to floor vapor barriers - is engineered with precision and forethought. The result is a cold storage facility that performs consistently, operates efficiently, and endures demanding conditions year after year.

Industries We Serve

Our cold storage buildings are trusted by clients across diverse sectors:

Food Processing Units & Agro Industries

Dairy, Ice Cream, and Meat Plants

Fruit & Vegetable Warehouses

Seafood Processing & Storage

Pharmaceutical & Biotech Facilities

Cold Chain Logistics & Distribution Centers

Floriculture & Horticulture Storage

Whether it's a small walk-in freezer room or a large industrial-scale facility, we tailor the structure to meet your exact requirements.

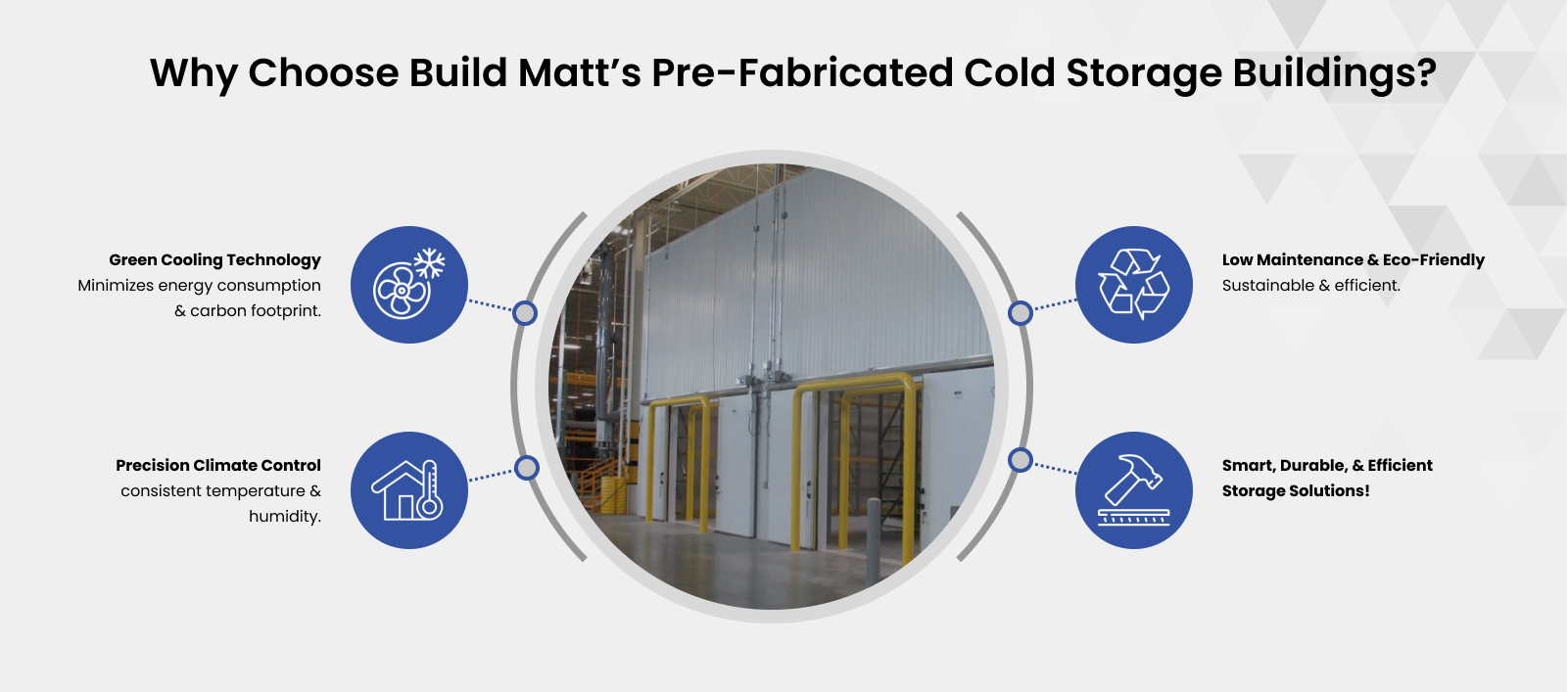

Storage Excellence You Can Rely On - That's Build Matt

At Build Matt, we do more than just construct buildings - we deliver high-performance cold storage infrastructure tailored to your specific operational needs. Here’s why businesses across India trust us for their cold storage projects:

Cold Storage Specialists – Not Just Builders

While many companies offer prefab or steel structures as a side service, cold storage is our focus area. Our design, panel selection, layout engineering, and ventilation flow are all optimized specifically for temperature-sensitive operations.

We understand:

End-to-End Solutions

From site layout planning to civil coordination, fabrication, installation, and even integration with refrigeration, Build Matt offers a complete turnkey solution. No delays, no miscommunication between vendors - we manage it all.

Our scope can include:

Rapid Execution with Quality Control

Our factory-built components reduce site dependency. This allows us to:

With a strong in-house team and skilled technicians, we’ve optimized our process for on-time delivery, cost-efficiency, and performance reliability.

How Industries Benefit from Build Matt's Cold Storage Solutions

Our prefabricated and PEB cold storage structures serve multiple business verticals. Below are the major categories we build for:

Food & Agro Storage

- Bulk storage of grains, onions, potatoes

- Controlled ripening chambers for bananas or mangoes

- Pack-house facilities with pre-cooling zones

Dairy & Meat Processing

- Refrigerated rooms for milk, cheese, and butter

- Blast freezers for meat processing

- Deep freezing for ice cream and frozen foods

Pharmaceuticals

- Cleanroom-grade cold chambers

- Controlled environments for vaccines and biopharma

- Segregated rooms for chemical-sensitive products

Floriculture & Horticulture

- Temperature-controlled spaces for cut flowers

- Preservative storage for exotic plants

- Humidity-optimized prefab greenhouses

Seafood & Marine Products

- Processing centers with cold docking

- Frozen storage of fish, prawns, and shellfish

- Proximity-based cold rooms for fishing harbors

Ready to Build Your Cold Storage Facility?

Whether you’re starting from scratch or upgrading an old setup, Build Matt is your trusted partner for high-performance cold storage buildings.

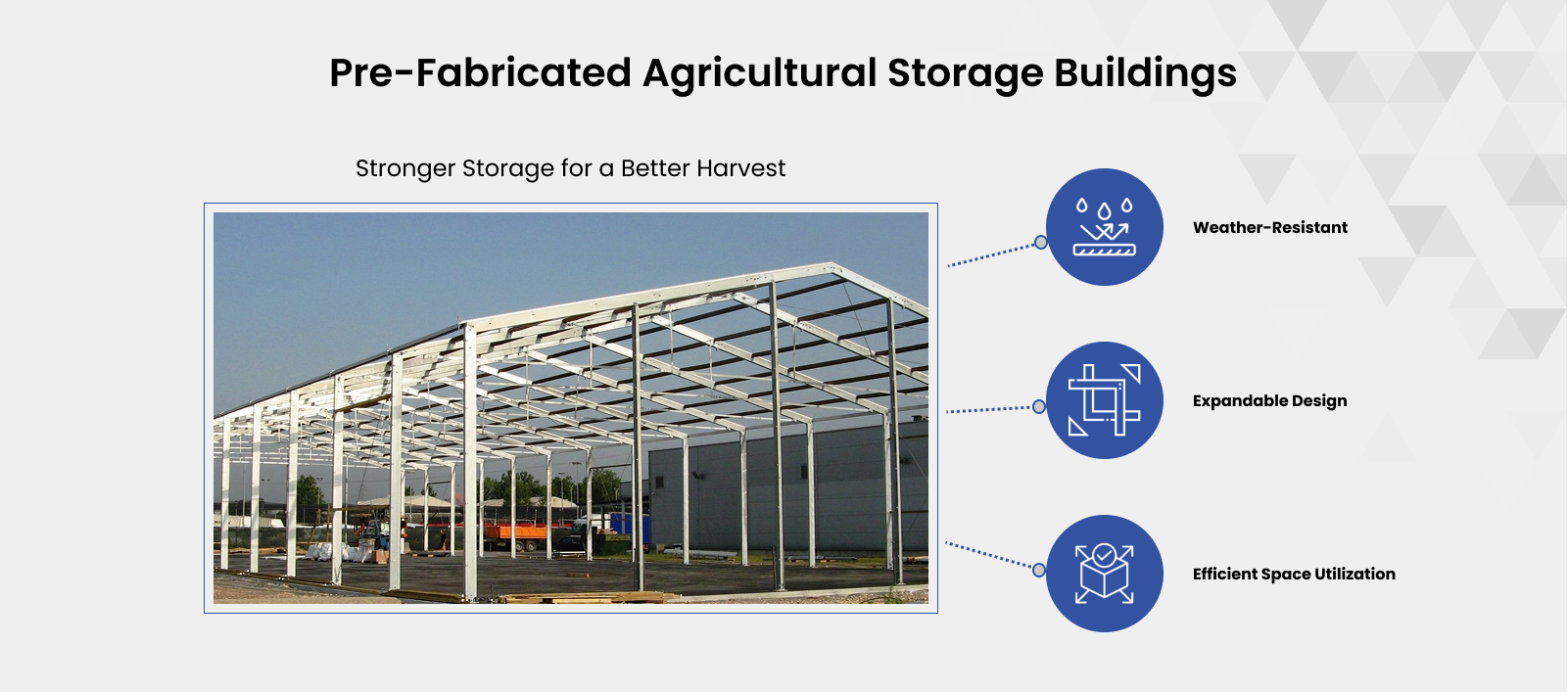

Agricultural Storage Infrastructure by Build Matt

Engineered for Efficiency, Durability & Climate Control

With years of engineering excellence in steel buildings and modular construction, Build Matt delivers high-performance Agricultural Storage Facilities using cutting-edge Prefabricated and Pre-Engineered Building (PEB)systems. Designed for diverse agri-climatic zones and evolving agri-supply chains, our structures ensure maximum protection against spoilage, moisture ingress, and temperature fluctuations, while supporting seamless bulk handling and long-term storage requirements.

From grains, pulses, and oilseeds to fertilizers, agri-implements, and packing materials, our solutions address both perishable and non-perishable agri-storage demands through custom-built, scalable structures that optimize operational throughput and reduce post-harvest losses.

Why Build Matt’s PEB & Prefabricated Buildings Are Technically Superior for Agricultural Storage

Agricultural storage infrastructure demands a fine balance between structural resilience, environmental responsiveness, and operational scalability. Traditional masonry or RCC construction often fails to deliver consistent performance across diverse agro-climatic conditions, particularly when rapid deployment, load-bearing adaptability, and climate control are essential. At Build Matt, we engineer PEB and Prefabricated storage solutions with precision, built to handle wide-ranging agricultural needs and environmental stresses.

Backed by decades of industry-specific design experience, our cold-formed and hot-rolled steel buildings, combined with scientifically selected panel systems, offer a structurally sound, modular, and functionally dynamic storage solution - purpose-built for rural and industrial agricultural operations.

Engineered Steel Structures – Designed for Agro-Industrial Environments

Our structural systems are developed using a combination of hot-rolled sections for primary load-bearing frames and cold-formed steel members for optimized weight-to-strength ratios, allowing for expansive clear-span designs of up to 50 meters. These spans are especially critical for unobstructed vehicular movement involving tractors, trolleys, forklifts, and other mechanized agri-handling systems.

Each framework undergoes a rigorous structural analysis incorporating:

Additional engineering elements include:

Climatic Envelope Systems – Engineered for Crop and Chemical Sensitivity

Our building envelopes are customized based on the specific storage application and regional climate profile.

Each building is engineered to regulate internal microclimates effectively, leveraging:

Modular Deployment – Designed for Agricultural Time Sensitivity

Recognizing the seasonal urgency in agriculture, our systems are built for minimal on-site construction and rapid commissioning. All major components - structural steel, cladding panels, doors, and accessories - are pre-engineered and precision-fabricated in a controlled environment, ensuring dimensional accuracy and eliminating common site errors.

Installation advantages include:

Heavy-duty Load Handling - Optimized for Bulk Agricultural Commodities

Our buildings are engineered to carry high static and dynamic loads associated with bulk commodity storage. Whether you're storing 50kg grain sacks, palletized cartons, liquid-filled drums, or mechanized bins, the structures and floor slabs are tailored for uniform load distribution and shock resistance.

Key load-engineered features:

Application-centric Customization – Built for Indian Agricultural Diversity

Our engineering process begins with a site-specific feasibility analysis, taking into account:

Soil-bearing capacity and contour profile

Rainfall and drainage characteristics

Solar exposure and prevailing wind patterns

Local transportation network for logistics flow

Whether it's a high-humidity seed preservation unit , a multi-commodity godown, or an export-grade processing center , Build Matt’s team tailors the entire layout - structure, envelope, access, utilities - to meet regional and crop-specific demands.

Technical Specifications

| Component | Specifications & Options |

|---|---|

| Structural Frame | MS Steel, Hot Rolled / Cold Formed, IS 800/MBMA compliant |

| Roofing Option | Color-Coated Galvalume Sheets, Sandwich Panels, Ridge Ventilators |

| Wall Systems | GI Corrugated / Sandwich PUF / EPS Panels (40–100mm) |

| Floor Load Design | Up to 5 tons/m² (customizable based on use) |

| Clear Span Capability | Up to 50 meters, expandable with modular bay additions |

| Eave Height | 4m – 12m standard; higher custom options available |

| Ventilation Systems | Turbo vents, ridge ventilators, side louvers |

| Lighting | Natural daylight panels + Industrial LED options |

| Surface Finish | Epoxy, VDF, or textured non-slip concrete |

| Doors & Shutters | Rolling shutters, sliding doors, dock doors with weather seals |

| Expansion & Relocation | Bolt-connected frame structure for easy scalability or dismantling |

Build Your Agri Storage Infrastructure with Confidence

Whether you're a progressive farmer, agri-entrepreneur, cooperative, or FPO, Build Matt offers future-ready, high-performance agricultural buildings engineered to protect your produce, streamline operations, and maximize value.

Customized Agri Storage Facilities Delivered Nationwide

Our Expertise

Frequently Asked Questions (FAQs) About Cold Storage & Agricultural Storage Buildings

Yes. We tailor all technical aspects - roof design, panel material, ventilation, insulation, and layout - based on your crop type, moisture sensitivity, and geographic location. Each structure is engineered considering local agro-climatic conditions and post-harvest handling requirements.

Depending on size and configuration, most projects are completed within 3 to 6 weeks, including on-site installation. Custom structures involving integrated cold rooms, multi-bay layouts, or mezzanine decks may require slightly more time.

Yes. All Build Matt structures can be provided with solar panel–ready roofing purlins, and we can integrate rainwater harvesting systems with sloped roofs, PVC drainage channels, and water storage tanks to support sustainable agri operations.

Absolutely. One of the key advantages of Build Matt’s prefabricated and PEB systems is modular scalability. Structures can be extended, partitioned, or even dismantled and relocated with minimal structural modification and without affecting the core integrity.

We offer Annual Maintenance Contracts (AMC), preventive inspections, insulation retrofitting, and expansion consulting. Our technical team is available for on-call site support, panel replacements, and layout modifications as your operational needs evolve.

Yes. Our engineering team has worked on multiple projects under various schemes, and we ensure all technical documentation and structural certifications required for subsidy eligibility are provided.

We offer high-load-capacity flooring systems including VDF (Vacuum Dewatered Flooring), Epoxy Coated RCC, and PU flooring, designed to withstand heavy axle loads, resist chemical spills (in fertilizer or pesticide storage), and facilitate easy cleaning.

Yes. We provide integrated prefabricated cold storage buildings with climate control infrastructure, including insulated PUF panels, vapor barriers, air curtains, and compatibility with Freon or ammonia-based refrigeration systems, tailored for seeds, horticulture, or dairy storage.

Prefabricated & Pre-Engineered Buildings

Prefabricated & Pre-Engineered Buildings

Steel Fabrication Solutions

Steel Fabrication Solutions

CNC Plasma Cutting

CNC Plasma Cutting

Steel Furniture & Custom Fabrications

Steel Furniture & Custom Fabrications

Specialized Steel & Storage Solutions

Specialized Steel & Storage Solutions

Additional Steel Products

Additional Steel Products