Engineered for Strength. Designed for Expansion.

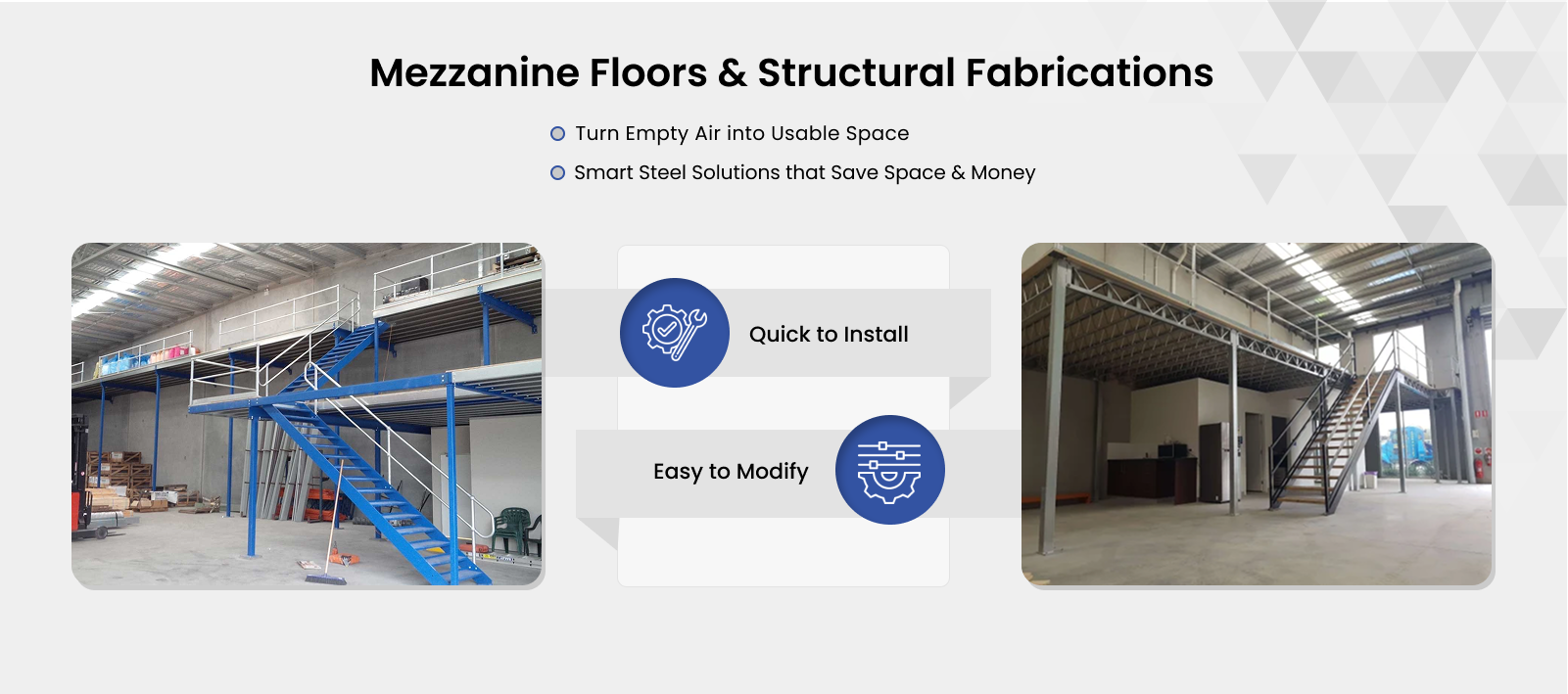

As Uganda’s commercial and industrial sectors grow, the demand for cost-effective vertical expansion is becoming critical. At Build Matt Uganda, we help businesses unlock underutilized vertical space with custom-engineered steel mezzanine floor systems that are fast to install, scalable, and structurally safe.

Whether it’s for a warehouse, automotive workshop, production line, retail showroom, or administrative office, our prefabricated steel mezzanines are designed to transform headroom into usable floor area — without altering your building’s footprint.

What Is a Mezzanine Floor?

A mezzanine is an intermediate floor built between two main floors of a structure, typically freestanding or supported by steel columns or walls. It offers an immediate way to increase usable space, especially in high-ceiling environments, without the time and cost of major civil works.

Maximize Space, Multiply Productivity

Build Matt’s steel mezzanines are:

Types of Mezzanine Floors We Fabricate

Free-Standing (Column-Supported) Mezzanines

Rack-Supported Mezzanines

Office or Hybrid Platforms

Building-Supported Mezzanines

Multi-Tier Mezzanines

All types are engineered for long-term adaptability — allowing you to relocate, reconfigure, or extend the structure as your operations evolve.

Applications across Industries

Build Matt Uganda supplies steel mezzanines for clients across various sectors:

No matter the application, our platforms are engineered for performance and built for Africa’s industrial reality — including temperature extremes, corrosion challenges, and site accessibility constraints.

Engineered to Perform – Key Structural Design Elements

At Build Matt, our mezzanine floor systems are not just fabricated — they’re engineered with precision, optimized for strength, safety, and long-term use.

Load Design & Structural Analysis

Each system is custom-designed to support specific live and static loads:

Our engineering team uses various Structures to design floor framing, bracing, staircases, and railing systems — ensuring safety under both operational and emergency scenarios.

Floor Decking & Finishing Options

Depending on use, we offer:

Integrated Access Systems

Our mezzanine platforms are supplied with:

Access elements are designed not only for functionality — but also to meet safety regulations and ergonomic standards.

Fabrication Process – Precision-Built for Site Performance

Every mezzanine floor fabricated by Build Matt Uganda undergoes a controlled, quality-driven production process using certified materials, modern equipment, and experienced hands. We understand that mezzanines are not just structural additions — they’re operational enablers.

CNC-Based Structural Processing

Welding & Structural Assembly

Surface Finishing

All steel members are bundled, labeled, and dispatched with corresponding fasteners, anchor bolts, and layout plans, ensuring a site-friendly and time-efficient installation process.

Why Build Matt?

Build Matt Uganda brings more than just fabrication capabilities — we bring partnership, precision, and performance to every mezzanine floor project.

End-to-End Expertise

From site surveys to fabrication drawings and load certifications, our team manages the entire lifecycle of your platform. You get a single point of accountability and zero coordination hassles.

Customization without Compromise

No two clients are the same — which is why we custom-engineer each mezzanine for its application, usage, and space. You get full control over:

Clients choose Build Matt because we deliver on time, fabricate to spec, and support long-term performance — even in the most demanding environments.

Ready to Expand Your Space? Let’s Build It.

When growth demands space, Build Matt Uganda delivers smart, scalable steel solutions that make room for what matters. Our mezzanine floors are built to maximize space, minimize construction time, and improve operational flow — whether you’re storing, working, displaying, or managing.

Our Strength

Over 20 years of engineering and fabrication expertise

Custom-built mezzanine systems with modular scalability

PAN-Uganda project execution with local fabrication support

Trusted by logistics, retail, industrial, and commercial sectors

Our Expertise

Frequently Asked Questions (FAQs) About Steel Mezzanine Floors

Depending on complexity and size, we typically fabricate and dispatch mezzanine floors within 3 to 5 weeks, including coatings and QA.

Yes. Our modular systems are bolt-assembled, allowing for easy dismantling and reassembly. Expansion modules can also be integrated into the original design.

Absolutely. Our team conducts site measurements, layout assessments, and load evaluations to ensure your mezzanine design is perfectly matched to your operational needs.

Yes. All access systems — including MS/SS stairs, safety railings, kick plates, and loading gates — are fabricated and supplied as part of our turnkey package.

Yes. We follow international best practices and local building code requirements. Structural documentation, load certificates, and safety checklists are included for project approvals.

Our kits are modular and compactly packed, making them ideal for tight-access installations. We also work around ongoing operations to minimize disruption.

Prefabricated & Pre-Engineered Buildings

Prefabricated & Pre-Engineered Buildings

Steel Fabrication Solutions

Steel Fabrication Solutions

CNC Plasma Cutting

CNC Plasma Cutting

Steel Furniture & Custom Fabrications

Steel Furniture & Custom Fabrications

Specialized Steel & Storage Solutions

Specialized Steel & Storage Solutions

Additional Steel Products

Additional Steel Products