Prefabricated Steel Warehouses Building Process: From Concept to Completion

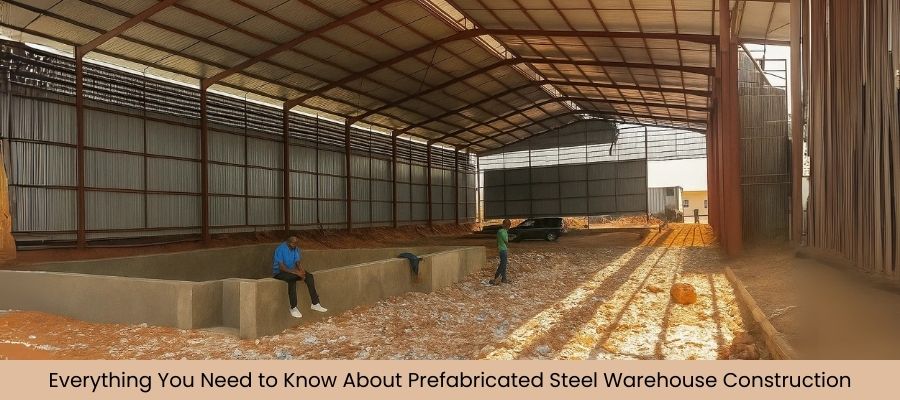

Building a prefabricated steel warehouse can be a complex yet rewarding process. It involves several stages that ensure the facility meets the desired specifications in terms of durability, efficiency and functionality. With the increasing demand for commercial warehouses, many businesses turn to warehouse work contractors and warehouse builders for their expertise in constructing these robust structures.

Prefabricated steel warehouses are particularly valued for their speed of construction, cost-effectiveness and flexibility. Unlike traditional construction, the modular nature of steel structures allows for faster assembly and fewer on-site construction errors, leading to timely project completion. This guide outlines each step in the process of building a prefabricated steel warehouse, from concept and design to fabrication and final installation.

How Do You Start the Process of Building a Prefabricated Steel Warehouse?

The first stage in constructing a prefabricated steel warehouse is the planning and conceptualization phase. This is where warehouse owners and contractors define the overall vision and goals for the facility.

Key Elements of the Planning Stage:

- Identifying Requirements: What purpose will the warehouse serve? Whether it’s for storage, distribution, manufacturing or another use, understanding the functionality of the warehouse will guide all subsequent decisions.

- Site Selection: Location plays a critical role in the design and construction. The land’s topography, soil quality and environmental factors such as climate must be evaluated to determine the most suitable design.

- Budgeting and Scheduling: Establish a clear budget and realistic project timeline. This helps ensure that costs stay within limits and the project stays on track.

- Regulatory Considerations: Depending on the location, there may be zoning laws, building codes and permits required to proceed with construction.

Warehouse owners often collaborate with a warehouse work contractor to ensure that all logistical and legal aspects are covered during the planning stage.

What Happens During the Design and Engineering Phase?

Once the planning is complete, the next phase focuses on the design and engineering of the warehouse. This is when the concept begins to take shape through detailed blueprints, calculations and specifications.

Design Considerations:

- Structural Design: The steel frame is the backbone of the warehouse. Designers and engineers work together to create a structure that can support the weight of the goods, machinery and the roof.

- Load Calculations: Engineers perform detailed calculations to ensure the warehouse can handle the loads it will be subjected to. This includes not only the weight of stored goods but also external factors like wind or snow loads.

- Custom Features: The design may include features such as insulation, fire safety systems, HVAC systems and specific interior layouts for racking or machinery.

- Blueprint Creation: Detailed engineering drawings are created, which provide instructions on how the warehouse should be built, including material specifications, structural components and installation techniques.

Warehouse builders use these blueprints to source materials and guide the construction process, ensuring accuracy and adherence to standards.

How Are Materials Sourced for Warehouse Construction?

Material selection is one of the most critical aspects of the construction process. The quality and suitability of materials affect the warehouse’s durability, energy efficiency and overall functionality.

Key Material Choices:

- Steel: Prefabricated steel panels and beams are chosen for their strength, flexibility and resistance to weather elements. Steel is also highly durable and requires minimal maintenance, which is a crucial consideration for commercial warehouses.

- Roofing Materials: The roofing system for prefabricated warehouses often includes corrugated steel or insulated panels to maintain temperature control and durability. Options may vary depending on the environmental conditions of the location.

- Insulation: If temperature control is necessary, insulation materials are chosen to keep the warehouse climate-controlled, which may be vital for certain types of inventory.

- Flooring: Concrete floors are typically used in prefabricated warehouses, as they provide a stable and durable base for heavy equipment and racking systems.

Warehouse builders work closely with suppliers to procure materials on time, ensuring that there are no delays in the construction process.

What Does Site Preparation and Foundation Work Involve?

Before construction can begin, the site preparation process is essential. This step ensures that the land is properly prepared to support the weight and structure of the warehouse.

Steps in Site Preparation:

- Clearing and Excavation: The site is cleared of any vegetation, debris or obstructions. Excavators may be needed to level the ground or create trenches for utilities.

- Foundation Work: The foundation is typically made of reinforced concrete, which provides a stable base for the warehouse. Engineers determine the type of foundation required based on soil conditions and the warehouse’s load-bearing needs.

- Drainage: Proper drainage systems are also established during this phase to prevent water from pooling around the structure, which could compromise the integrity of the foundation.

The foundation must be designed and built with precision, as it ensures the overall stability of the entire warehouse.

How is the Steel Frame Assembled?

Once the foundation is ready, the steel frame is assembled. This is the part of the process where the warehouse begins to take its full shape.

Steel Frame Assembly Process:

- Delivery of Components: Pre-fabricated steel components such as columns, beams and trusses are delivered to the site.

- Frame Erection: The steel components are then lifted into place using cranes and other heavy machinery. The frame is carefully secured to ensure structural integrity.

- Welding and Bolting: The steel components are welded or bolted together to form a sturdy skeleton. This phase typically moves quickly, as prefabricated components are designed for easy assembly.

This is a critical stage because the frame forms the main skeleton of the warehouse and will support all other components, including the roof and walls.

What is Involved in Wall and Roof Installation?

Once the frame is in place, the focus shifts to wall and roof installation. This step completes the basic structural framework, providing protection from the elements.

Wall and Roof Installation:

- Wall Panels: Pre-fabricated steel panels or insulated panels are installed along the walls of the warehouse. Depending on the design, walls may also include windows or doors for access.

- Roofing: The roof, made from pre-fabricated steel sheets, is installed over the steel frame. Depending on the climate, additional insulation or weatherproofing may be applied.

- Sealing and Safety Measures: All seams and joints are sealed to prevent water infiltration. Safety features, such as fire suppression systems, are also incorporated into the roof design if necessary.

Proper installation of the roof and walls ensures that the warehouse is weatherproof and energy-efficient.

After the warehouse structure is complete, it’s time to focus on the internal systems. These systems are essential for operational efficiency and safety.

Installation of Internal Systems:

- Electrical Systems: This includes power lines, lighting and electrical outlets. Wiring and circuit panels are installed according to the design specifications.

- Plumbing and HVAC: If the warehouse includes bathrooms, kitchens or any other plumbing needs, this is the phase where pipes and drains are installed. HVAC systems are also set up to control the indoor climate.

- Security Systems: Depending on the security requirements, systems such as surveillance cameras, access control systems and alarms are integrated into the warehouse design.

These systems are crucial for the operation of the warehouse, ensuring that it remains safe, functional and comfortable.

Before the warehouse is handed over for use, a thorough inspection process is necessary to ensure everything meets the design and regulatory standards.

Key Aspects of Final Inspection:

- Structural Integrity: The steel frame, walls and roof are inspected to ensure everything is securely in place and meets safety standards.

- System Functionality: All electrical, plumbing and HVAC systems are tested to confirm they function properly and comply with local codes.

- Regulatory Compliance: A final review ensures that the construction complies with local building codes, safety regulations and environmental standards.

Once the warehouse passes all inspections, it is ready for occupancy.

How is the Warehouse Handover Process Managed?

The final step in the warehouse construction process is the handover. This is when the warehouse is officially transferred to the owner or business.

Key Aspects of Handover:

- Site Cleanup: All construction debris is cleared and the site is prepared for operation.

- Training: If needed, staff may be trained on safety protocols or how to operate certain systems within the warehouse.

- Operational Setup: Any storage equipment, machinery or inventory is moved into the warehouse to prepare for day-to-day use.

Once the warehouse is fully equipped and operational, it is ready to begin serving its intended purpose.

Conclusion:

Building a prefabricated steel warehouse involves several critical steps, from initial planning and design to the final installation and handover. By following a structured approach and working with skilled warehouse builders and warehouse work contractors, businesses can ensure a successful and efficient construction process. Prefabricated steel warehouses offer numerous benefits, including reduced construction time, cost efficiency and long-term durability, making them an ideal solution for many commercial storage needs.

FAQs About Prefabricated Steel Warehouses

Prefabricated steel warehouses are cost-effective, quicker to construct and offer superior durability. They are also versatile and can be customized to meet specific storage or operational needs.

The timeline for building a prefabricated steel warehouse can vary, depending on size, complexity and site conditions.

Materials commonly used include high-quality steel for the frame, concrete for foundations, insulated panels for walls and roofs and various systems for plumbing, electrical and HVAC installations.

The cost of building a prefabricated steel warehouse depends on factors like the size of the structure, location, material quality, custom features (such as insulation or specialized systems) and labor costs.

Yes, prefabricated steel warehouses can be energy-efficient, especially when they incorporate insulation, proper ventilation and energy-efficient lighting and HVAC systems. This helps regulate the internal temperature and reduce energy consumption.

Founder & CEO

Mukesh Patel is the Founder & CEO of Build Matt ltd, specializing in Pre-Engineered Buildings (PEB) and general steel fabrication. With advanced technology, modern machinery, and a skilled workforce, he delivers efficient and high-quality solutions across East and Central Africa, including Uganda, Kenya, Tanzania, Congo, South Sudan, Rwanda, and Burundi.

- Steel Walkways Usage in Suspended Bridge and Overhead Platforms

- Steel Walkways Usage in Suspended Bridge and Overhead Platforms

- Steel Walkways by Build Matt Engineering the Path to Safety

- Roof Ventilation: Everything Homeowners Need to Know

- Steel Mezzanine Floors in Uganda: Comprehensive Guide by Build Matt Ltd