Polycarbonate

Polycarbonate hollow sheet installations can be extremely cost-effective because of its durability and long-lasting phenomenon. Hollow sheet installations remain one of the most used factory shades. A variety of techniques is used in the modern metal fabrication process with PC hollow sheet, shelters and Skylight installation for quality returns. For executing various types of hollow sheet installations, Build Matt has a wide space for storage purposes and machining. Spacious welding department, Electrical-drilling machine, Generators, Vibrating Roller, Compressors, Grinder and cutting machines, etc. are the modern machinery, and services indulged for this purpose.

Build Matt Ltd. is a company with a working experience of 20 years in the field of Steel fabrication & aluminum works. We have clients from various firms in and around the East Africa region like Uganda, S.Sudan, Rwanda, Burundi, Congo & Kenya, etc. We are equipped with skilled and experienced staff, works independently to provide fabrication solutions and polycarbonate sheet installations as per your requirements with complete satisfaction.

-77.jpg)

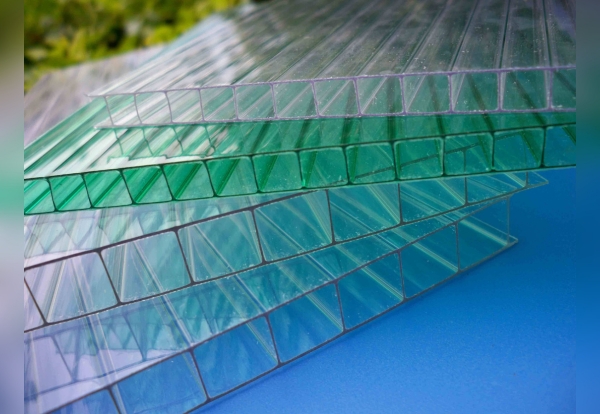

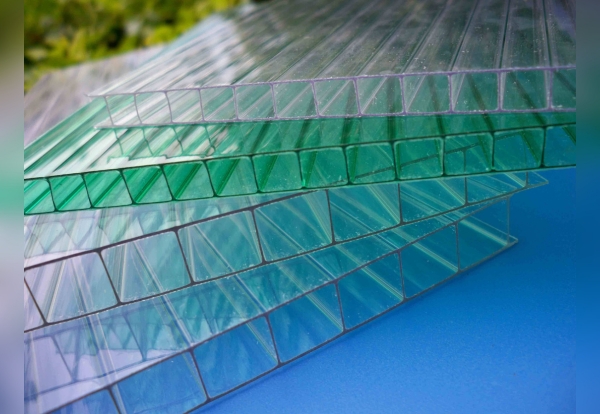

8mm Tween Wall Polycarbonate Sheet Materials Specifications

Polycarbonate Hollow Sheet (PC hollow sheet)

Polycarbonate sheet uses the imported polycarbonate raw material. On the Polycarbonate sheet surface distributed with high concentrations of UV co-extruded UV protection layer uniformly, it can completely prevent the polycarbonate sheet damage from UV and prolong the life of the sheet. Polycarbonate shade mainly used in municipal construction, home decoration, and business application requirements. The sheet with high impact resistance, anti-aging, UV protection, environmental, aesthetically pleasing, light weight. It’s easy for processing and installation.

Polycarbonate Sheet Features (PC Sheet)

Transmission of light:

Excellent lighting, transparency can be equivalent to that of glass. The UV coated sheet in the sun exposure will not become yellowing, atomization, poor light transmission. The transmission loss is only 6% after ten years, but the PVC sheet is as high as 15%-20%, fiber glass sheet is as high as12% - 20%.

UV Coating:

The hollow sheet is coating with anti-ultraviolet (UV) on one side, the other side is with anti-condensation treatment, it is with the functions of anti-ultraviolet, insulation, anti-drop. It can prevent the ultraviolet getting through; it is suitable for protecting valuable works of art and exhibits, to make it from UV damage.

Lightweight:

The proportion of PC is only 1/12 of normal glass, it’s unbreakable, to save the cost of transportation, unloading, installing and frame supporting.

Flame:

The national standard GB/T2408-2008 confirmed that the Polycarbonate hollow sheet is a flame, HB level. The itself ignition of hollow sheet is 580 Celsius degrees, self-extinguishing when away from the fire, does not produce toxic gases when burned, and will not contribute to the spread of fire.

Bendable:

Using cold-formed way at the site to install as vaulted according to the design. The minimum bend radius is 175 times of the thickness. It also can be warm-bended.

Sound insulation:

The Polycarbonate hollow sheet has better sound insulation compared with the same thickness of glass and acrylic sheet. Under the same conditions of same thickness, the acoustic volume of PC hollow sheet is 3-4DB higher than that of glass. PC is the first selection of noise barrier material in the highway in the world.

Energy-saving:

Keep cool in summer, keep warm in winter. The PC hollow sheet is lower thermal conductivity (K value) than common glass and other plastic. The heat insulation effect is 7% and 25% higher than the same glass. The insulation of PC hollow sheet is up to 49%.so that the heat loss is greatly reduced, it can be used in the construction with warm equipment, it’s the environmental protection material.

Weather resistance:

The PC hollow sheet can maintain the stability of the physical indicators in the range of -40 ? to 120 ?. After artificial weathering test of 4000 hours, yellowing is 2 degree, light transmittance value is only lower 0.6%.

Anti-condensation:

The outdoor temperature is 0 ?, the indoor temperature is 23 ?. There is non-condensing inside surface of the material when the indoor relative humidity below 80%.

Polycarbonate Sheet/Shelter Application

Our Expertise

Prefabricated & Pre-Engineered Buildings

Prefabricated & Pre-Engineered Buildings

Steel Fabrication Solutions

Steel Fabrication Solutions

CNC Plasma Cutting

CNC Plasma Cutting

Steel Furniture & Custom Fabrications

Steel Furniture & Custom Fabrications

Specialized Steel & Storage Solutions

Specialized Steel & Storage Solutions

Additional Steel Products

Additional Steel Products