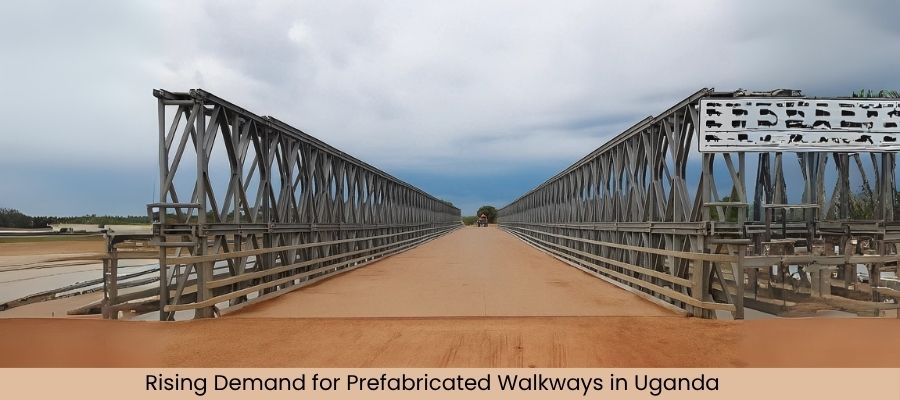

The Growing Demand for Prefabricated Walkways in Uganda’s Various Industries

Objective

Explain why prefabricated walkways are in growing demand across Uganda’s industries and outline the technical considerations that ensure safe, compliant and reliable deployment of modular access systems – including specification, design coordination, site interfaces and lifecycle practices for Steel Walkways.

Introduction

Across Uganda, projects in energy, agro-processing, logistics parks, hospitals, campuses and mixed-use facilities are expanding. As sites scale up, elevated access routes become essential for inspections, servicing and safe egress. Prefabricated Steel Walkways answer that need with standardized modules that can be installed quickly and adapted to diverse structures. This article explains the technical drivers behind their adoption in Uganda, how teams specify them and what controls keep installations safe, compliant and durable. The focus remains practical: modular design parameters, interface details and verification steps that any engineering or site team can adopt.

Market Context: Why Prefabricated Walkways Fit Uganda’s Build Pattern

Uganda’s project timelines often compress around seasonal windows, utility availability and phased commissioning. Prefabricated Industrial Walkways can be produced off-site and installed during tight shutdowns or weekend windows. They may reduce on-site cutting and hot work, which simplifies permits and lowers erection risk. Because many facilities expand incrementally, modular spans and bolted connections support staged upgrades without redesigning primary frames. This adaptability is one reason steel structure walkways see wider use in plants, depots, high-bay warehouses, data rooms and roof-level equipment corridors.

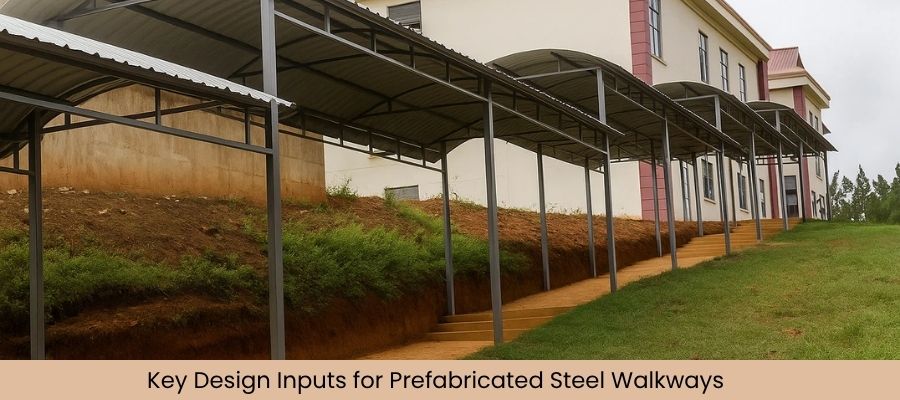

Design Inputs for Prefabricated Steel Walkways

A reliable design starts with clear load and geometry inputs:

- Design loading: Define uniformly distributed load and point load assumptions for foot traffic, occasional equipment and maintenance tools.

- Span and deflection: Select span lengths and allowable deflection criteria so floor vibration remains comfortable during movement.

- Decking type: Specify open grating or solid plate; open grating improves drainage and slip resistance in outdoor locations.

- Guarding: Detail guardrail height, infill opening limits and toe boards to control edge exposure and dropped-object risk.

- Fire and finish: Choose coating systems that match the environment – interior dry, exterior wet or coastal spray conditions.

These parameters guide manufacturers of Metal Walkway modules to fabricate consistent, repeatable components.

Structural Integration with Primary Frames

Prefabricated access sits on something – and that interface must be defined. For steel structure walkways, engineers confirm:

- Support locations: Secondary beams or clips are aligned with walkway stringers; avoid eccentric loads that twist purlins.

- Connection types: Bolted shear tabs and angle cleats are common; they may be pre-punched to match module hole patterns.

- Differential movement: On long buildings, thermal movement may require slotted holes or sliding bearings at one end.

- Clearance: Maintain overhead and lateral clearance to cable trays, ducts and roof bracing.When early drawings capture these items, Maintenance Walkways install without field improvisation.

Material Choices and Coatings for Steel Walkways

Material selection determines durability and upkeep:

- Sections: Rolled channels, angles or cold-formed stringers keep weight low; box sections may be used where torsion control is important.

- Decking: Galvanized grating is common outdoors; chequer plate or serrated grating is used for improved grip.

- Coatings: Hot-dip galvanizing, zinc-rich primers or duplex systems (galvanize + paint) are specified by exposure class.

- Fasteners: Use compatible bolts to avoid bimetallic corrosion.

Well-specified Steel Walkways maintain performance in sun, rain and dusty environments found in many Ugandan sites.

Access and Egress: Stairs, Ladders and Landings

Walkways live within circulation systems. For Commercial Walkways connecting roof plant or mezzanine corridors:

- Stair design: Define riser and going, handrail height and landing depth.

- Ladders: For short access to equipment platforms, fixed ladders may be used with cages or fall-arrest systems where required.

- Landings: At direction changes and doorways, ensure landings provide turning space and door swing clearance.

- Continuity: Handrails and guards continue through transitions; no gaps at corners.

These elements create continuous, safe routes that meet inspections without last-minute rework.

Fabrication Tolerances and Quality Controls

Modular Industrial Walkways depend on accuracy:

- Dimensional tolerances: Control overall length, hole spacing and squareness so modules align on site.

- Welding: Follow qualified procedures; control heat input to limit distortion on thin sections.

- Trial fit: Where interfaces are complex, trial assemble typical modules to validate bolt access.

- Identification: Piece-marking and kit-packing help crews find the right module for each bay.

Quality records make commissioning smoother and reduce punch lists.

Installation Sequencing for steel structure walkways

A clear sequence may prevent unsafe temporary states:

- Verify supports (anchors, bearings and elevations).

- Lift and place stringers using engineered lift points or balanced slings.

- Temporary brace until cross-members and deck fixings lock the module.

- Fit deck and guards; complete torque checks and tag as inspected.

- Integrate stairs/ladders; confirm landing geometry and egress markings.

This stepwise approach applies to roof-level Metal Walkway bridges and interior mezzanine links alike.

Safety Compliance and Work-at-Height Controls

During installation, height work is common. Teams can ensure compliance by:

- Access equipment: Use MEWPs or scaffold with full decking; limit ladder-only work.

- Fall protection: Fixed anchors or lifelines, harnesses with shock-absorbing lanyards and a documented rescue plan.

- Edge control: Temporary guardrails on partially complete spans; toe boards where tools may roll.

- Dropped-object prevention: Tethered tools and bolt bags to protect personnel below.

These controls are standard for Steel Walkways erected above occupied areas.

Industry Use Cases in Uganda

Prefabricated walkways serve varied sectors:

- Agro-processing and milling: Overhead access for sifters, conveyors and dust collectors.

- Power and utilities: Turbine hall galleries and transformer access; Walkways around switchgear.

- Warehousing and logistics hubs: Roof plant routes to HVAC units and solar arrays; interior mezzanine connections.

- Healthcare and education: Plantroom and service-level Commercial Walkways for safe technician access.

- Telecom and data facilities: Cable tray corridors and inspection routes, often with anti-static considerations. Because modules are configurable, the same kit can adapt across sites as demands evolve.

Operations and Maintenance Planning

Even prefabricated systems need care:

- Routine checks: Look for loose fixings, worn anti-slip surfaces and localized corrosion – especially at deck cut edges.

- Cleaning: Remove debris that can trap water or soil; blocked grating accelerates corrosion.

- Coating touch-up: Follow specified primers and overcoats; maintain compatibility with galvanizing.

- Access controls: Signage, lighting and restricted access policies maintain safe use after handover.

A simple plan keeps walkways reliable without major interventions.

Commercial Considerations Without Overstatement

Procurement in Uganda may weigh capacity, lead time and site support. Modularization reduces custom fabrication hours and may improve availability of spare panels. Clarity on scope – coatings, guards, stairs, landings and fixings – prevents change orders. For phased developments, standardizing bay length and hole patterns across Steel Walkways simplifies future expansions.

Integration Tips for Designers and Site Teams

To streamline delivery:

- Freeze interfaces early: Coordinate with roofing, cladding rails and services.

- Standardize modules: Repeat span lengths and connection details where possible.

- Provide access drawings: Show MEWP reach, crane positions and exclusion zones.

- Label routes: Name corridors and platforms so O&M teams can reference them in manuals.This template works across Industrial Walkways in plants and Commercial Walkways in mixed-use developments.

Conclusion

Uganda’s expanding facilities require dependable, safe elevated access. Prefabricated walkways meet that need by combining modular design with predictable installation and clear maintenance pathways. When teams define loads, guard systems, coatings and interfaces up front – and install with controlled lifting, bracing and inspection – Steel Walkways integrate seamlessly into new builds and retrofits. The result is a repeatable approach that suits energy sites, processing halls, campuses and logistics hubs, while keeping crews safe and assets accessible for routine tasks.

FAQs About Steel Walkways

They appear in plants, warehouses, public facilities and roof-level service areas. Teams use them to reach equipment, bridge roof units and create safe inspection routes.

Projects typically define a uniform pedestrian load and occasional point loads for equipment. The exact values depend on local codes and use type; engineers set these during design.

Yes, modular spans and standardized connections can allow extensions and reconfiguration, provided the primary structure is designed for the additional loads.

Hot-dip galvanizing or zinc-rich primers with durable topcoats are common. The selection depends on environment and maintenance expectations.

They may be inspected at handover, after the first months of operation and then at defined intervals - often annually - focusing on fixings, anti-slip surfaces and coatings.

Founder & CEO

Mukesh Patel is the Founder & CEO of Build Matt ltd, specializing in Pre-Engineered Buildings (PEB) and general steel fabrication. With advanced technology, modern machinery, and a skilled workforce, he delivers efficient and high-quality solutions across East and Central Africa, including Uganda, Kenya, Tanzania, Congo, South Sudan, Rwanda, and Burundi.

- Steel Walkways by Build Matt Engineering the Path to Safety

- Roof Ventilation: Everything Homeowners Need to Know

- Steel Mezzanine Floors in Uganda: Comprehensive Guide by Build Matt Ltd

- Steel Trusses and Rafters in Uganda: Engineering the Future

- Steel Staircase Fabrication: A Step-by-Step Engineering Manual