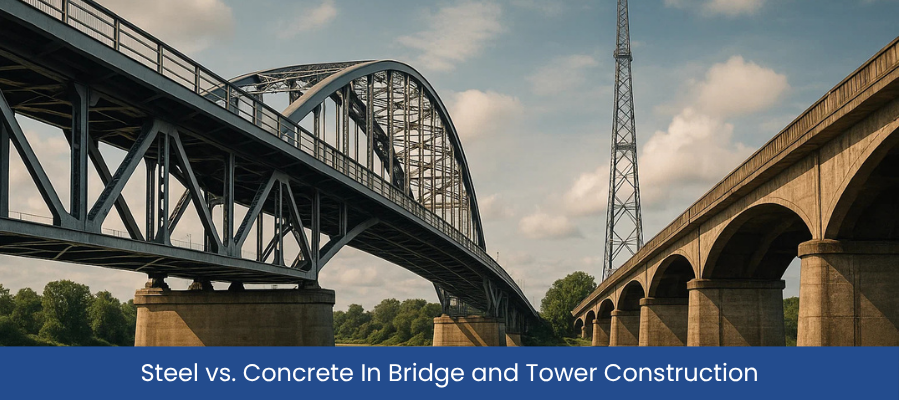

Steel vs. Concrete in Bridge and Tower Construction: A Comparative Study

What Makes Steel the Ideal Material for Bridge and Tower Construction?

Key Steel Advantages:

- High Strength-to-Weight Ratio: Steel’s excellent strength-to-weight ratio allows for lighter, more efficient structures while still supporting heavy loads. This property is crucial for bridges and towers that must span long distances or carry substantial loads without compromising safety or design.

- Flexibility and Ductility: Steel’s flexibility allows it to absorb shocks, vibrations and movements, making it an ideal choice for bridges in regions with seismic activity or high winds. Steel structures can flex without cracking, reducing the likelihood of catastrophic failure.

- Corrosion Resistance: Modern steel is often treated with anti-corrosion coatings or galvanized to ensure it stands up to environmental stressors such as moisture, salt and extreme temperatures. This ensures that steel bridges and towers remain in good condition for decades.

How Do Steel and Concrete Compare in Terms of Load-Bearing Capacity?

Steel’s Load-Bearing Advantage:

- Structural Efficiency: Steel’s ability to carry immense loads with minimal material is one of the primary reasons it is favored for bridge and tower construction. Steel’s ability to bear higher loads per unit of weight allows engineers to design more efficient, lighter structures that require less material while maintaining strength.

- Dynamic Load Handling: Steel is more capable of handling dynamic loads, such as traffic movement on bridges or wind forces on towers. The material’s ductility means that it can absorb and distribute these forces more effectively than concrete, which can crack under stress.

Concrete’s Load-Bearing Limitation:

- Brittleness: While concrete is strong in compression, it is less effective at handling tensile forces and is more brittle compared to steel. Concrete structures can develop cracks under tensile stress, weakening the load-bearing capacity. In applications such as towers and bridges that experience a mix of static and dynamic forces, steel is far more suitable.

- Heavier Material: Concrete’s density makes it heavier than steel and although it is good in compression, it often requires a larger volume of material to achieve the same load-bearing capacity as steel. This results in a bulkier structure, which is less efficient in terms of material use.

When Does Steel Outperform Concrete in Terms of Construction Time?

Steel’s Construction Speed:

- Prefabrication: Steel components for bridges and towers can be fabricated off-site in a controlled factory environment. This prefabrication process reduces the on-site construction time significantly. Once the components are delivered, they can be assembled quickly, resulting in faster completion times for the overall project.

- Reduced Curing Time: Unlike concrete, which requires curing time to reach its full strength, steel components are ready to be assembled as soon as they are manufactured, eliminating delays caused by curing and setting processes.

Concrete’s Slower Construction Process:

- Curing Time: Concrete requires a curing process, which can take several days or even weeks depending on the type of concrete used. During this time, construction must pause, delaying the overall timeline.

- On-Site Formwork: Concrete structures are often cast on-site, which requires complex formwork and more labour-intensive processes. The waiting time for concrete to set adds to the construction time.

What about the Long-Term Durability and Maintenance of Steel and Concrete Structures?

Steel’s Durability and Low Maintenance:

- Resistance to Environmental Stress: Steel structures are resistant to many of the environmental stresses that impact concrete, including moisture, salt and temperature fluctuations. When treated or coated with anti-corrosive materials, steel can last for decades without significant degradation.

- Reduced Repair Needs: Unlike concrete, which may require frequent repairs due to cracking or erosion, steel towers and bridges require minimal maintenance. Minor repairs are often quicker and easier compared to fixing concrete cracks or structural damage.

- Flexibility for Inspections and Modifications: Steel structures can be inspected and modified more easily than concrete, providing a longer lifespan and greater adaptability for future upgrades or changes.

Concrete’s Maintenance Challenges:

- Cracking and Wear: Over time, concrete can crack due to freeze-thaw cycles, chemical reactions or even stress. These cracks can weaken the structure and often require costly repairs to maintain the integrity of the bridge or tower.

- Heavy Maintenance: Concrete bridges and towers are prone to erosion, especially in areas exposed to high moisture or salt. This leads to more frequent inspections, repairs and sometimes complete replacements of parts of the structure.

Where Is Steel Preferred Over Concrete for Bridge and Tower Construction?

The use of steel over concrete is particularly advantageous in certain locations and circumstances where specific challenges arise, including seismic activity, high traffic volumes and extreme weather conditions.

- Superior Performance in Seismic Zones: Steel’s ability to absorb and dissipate energy makes it ideal for construction in seismic zones. Unlike concrete, which may crack or fail under seismic forces, steel’s flexibility allows it to withstand earthquakes and other dynamic forces, making steel bridges and towers more resilient in these regions.

- Steel’s Use in High-Traffic Areas: In regions with high traffic or heavy loads, steel bridges outperform concrete in maintaining structural integrity under constant stress. Steel bridges, due to their superior tensile strength, are less likely to experience fatigue failure over time.

- Effectiveness of Steel in Harsh Environments: Steel is also the material of choice in environments that experience extreme temperatures or corrosive elements (e.g., coastal areas with saltwater exposure). Steel’s resistance to corrosion makes it the better choice over concrete in such areas.

Conclusion

In the battle between steel and concrete for bridge and tower construction, steel clearly stands out as the superior material. Its strength, flexibility and resilience in handling both static and dynamic loads make it the ideal choice for communication towers, power transmission towers and large bridges. The faster construction time, lower maintenance costs and longer lifespan of steel structures further solidify steel as the material of choice for large-scale infrastructure projects.

While concrete may still have applications in specific scenarios, steel’s advantages in durability, construction speed and resilience to environmental factors make it the optimal material for bridge and tower construction, especially in high-stress and high-traffic environments.FAQs

Steel’s higher strength-to-weight ratio, ability to handle dynamic loads and resistance to environmental factors make it the optimal material for large-scale infrastructure projects like bridges and towers.

While steel may have a higher initial cost, its durability and low maintenance requirements make it more cost-effective in the long term compared to concrete, which requires frequent repairs and maintenance.

Steel is much more flexible and capable of absorbing and dissipating seismic energy, making it a far superior option for earthquake-prone areas. Concrete structures, on the other hand, are more likely to crack or collapse under seismic forces.

Yes, steel’s strength-to-weight ratio allows it to span longer distances without the need for additional supports. This makes steel ideal for bridges over large bodies of water or in locations requiring minimal disruption to the landscape.

Steel has higher tensile strength, allowing it to withstand continuous dynamic loads from high-traffic areas without developing cracks or fatigue, unlike concrete, which can deteriorate under sustained pressure.

Founder & CEO

Mukesh Patel is the Founder & CEO of Build Matt ltd, specializing in Pre-Engineered Buildings (PEB) and general steel fabrication. With advanced technology, modern machinery, and a skilled workforce, he delivers efficient and high-quality solutions across East and Central Africa, including Uganda, Kenya, Tanzania, Congo, South Sudan, Rwanda, and Burundi.

- Steel Walkways by Build Matt Engineering the Path to Safety

- Roof Ventilation: Everything Homeowners Need to Know

- Steel Mezzanine Floors in Uganda: Comprehensive Guide by Build Matt Ltd

- Steel Trusses and Rafters in Uganda: Engineering the Future

- Steel Staircase Fabrication: A Step-by-Step Engineering Manual