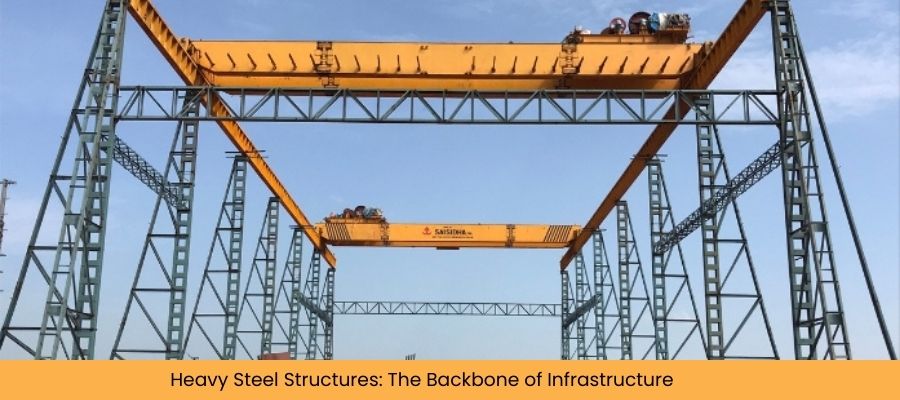

Steel Fabrication for Bridges, Towers, Girders, & Flyovers: Engineering the Backbone of Infrastructure

Steel structures form the skeletal framework of much of the modern world’s infrastructure. From long‑span bridges to transmission towers, from highway flyovers to towering telecom masts, heavy steel structures are indispensable. Build Matt specializes in precision steel structure manufacturing and fabrication: as a steel structure contractor, builder and manufacturer, Build Matt ensures structural steel fabrication meets exacting engineering, quality and performance standards. This article examines how Build Matt delivers complex heavy steel structure projects – bridge girders, towers, flyovers – by deploying advanced fabrication techniques, software tools and rigorous quality control.

Why Steel Fabrication is Bridging the Future for Long Span Bridges and Flyovers?

Build Matt’s work in bridge girder fabrication includes welded plate girders, I‑girders, box girders, diaphragms and splice plates, all essential for road and rail bridges and flyovers. Welded plate girders are built by welding steel plates (webs and flanges) into large, continuous members; box girders encapsulate a closed cross‑section that resists torsion and is preferred for long spans. Splice plates are used to join sections where single large pieces cannot be transported or built in one piece.

In fabricating steel flyover structures, Build Matt manages design detailing from the outset to ensure that welded plate girders and I‑girders conform to load demands, deflection limits and vibration criteria. Diaphragms (internal stiffeners between girders) may be introduced to distribute shear, reduce local buckling and maintain cross‑sectional integrity. Splice plate interfaces are carefully detailed for fatigue and serviceability – bolted or welded as per specific standards.

Precision comes not only in geometry (camber, alignment, dimensional tolerances) but also in material quality, weld procedures and surface treatment. For example, ensuring that welded joints are free of defects requires qualified welders, welding procedure specification (WPS) and non‑destructive testing (NDT) methods. Build Matt uses these in combination with stringent inspection protocols to verify that bridge girder fabrication meets both local and international norms. The result is steel flyover structures and long‑span bridges that can bear heavy loads, resist service stresses and endure over time.

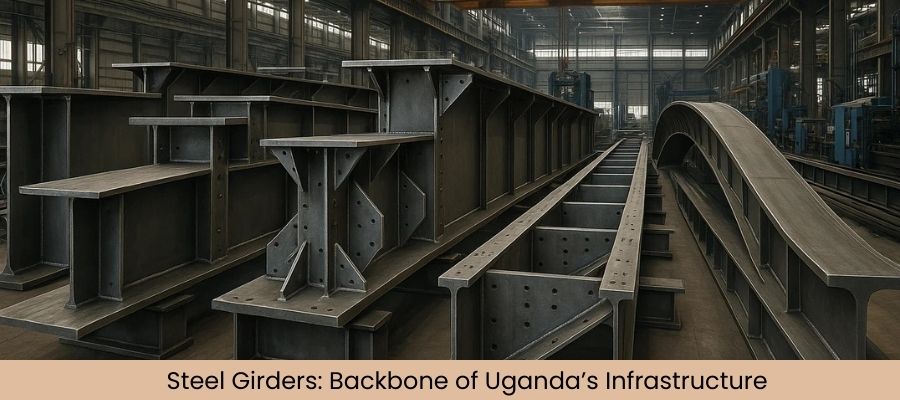

How Girders for Bridges and Flyovers is the Backbone of Uganda’s Infrastructure?

Girders in major bridges and flyovers have to carry massive loads – vehicle loads, dynamic loads, wind loads, sometimes seismic loads. Build Matt fabricates heavy steel girders such as deep welded I‑beams, built‑up box girders and pre‑cambered girders. Cambering (introducing upward curvature) compensates for deflection under load so that under service loads the girder appears straight.

Key components include gussets and stiffeners. Gussets are plate elements joining other members – such as between diagrid bracing or between flange and web – and need precise manufacturing to avoid stress concentrations. Stiffeners are used inside webs to prevent buckling under compressive stress or shear.

In terms of materials, Build Matt sources high‑grade steel plates and sections, tests for yield, tensile strength, toughness and weldability. The manufacturing sequence includes cutting, shaping, pre‑assembly, welding, camber forming and then final finishing. Dimensional control is vital: gauge of the web and flanges, alignment of camber, straightness, flatness, all in tight tolerances.

These girders are especially used in heavy steel structure applications – for bridge girders, industrial girders contractors’ projects, portal frames, large factories, etc. Build Matt ensures that structural fabrication for EPC (engineering, procurement, construction) projects integrates these high‑strength girders seamlessly into the overall infrastructure design.

How Tower Fabrication Plays Major Role in Telecom and Transmission Projects?

Towers – whether for telecom, transmission or signalling – have unique demands: resistance to wind loading, fatigue, corrosion and dynamic behaviour. Build Matt specializes in lattice towers, angular and tubular steel structures and monopoles. For transmission towers, steel tower fabrication includes designing cross arms, bracing systems, tubular or angular legs that distribute loads optimally.

Anchoring parts – base plates, anchor bolts, foundations – must be engineered for lifting moments, overturning forces and soil loads. Hot‑dip galvanizing is often used on tower legs and other exposed elements to protect against corrosion under tropical or coastal exposure.

The process starts with tower design: structural analysis to determine wind load, ice load (if relevant), seismic factor. Then, detail modelling to derive fabrication drawings. Segmental fabrication may be used – meaning tower is built in modules for ease of transportation and assembly on site. Cross arms and bracings are detailed and fabricated with precision so that bolt‑hole alignment is maintained. Any errors here lead to assembly problems or weakened joints.

Build Matt’s tower structures are meant to last decades; design and construction must account for fatigue (wind gusts, vibration), material degradation, ease of maintenance and safety (safe ladder access, platforms). The steel fabrication for towers is done with these in mind, ensuring high reliability.

How Fabricating Flyovers Supports Urban Highway Projects across Uganda?

In urban settings flyovers demand high accuracy, fast turnarounds, minimal site disruption. Build Matt provides end-to-end fabrication services: from shop drawings and detailing through dispatch and site‑fitment.

Defining every component – girders, bearings, expansion joints, splice connections. Shop drawings must include loadings, welds, bolt specifications, camber, material grades. Fabrication follows with cutting, welding and assembly. Pre‑fabricated flyover beams may be fully assembled in controlled shop conditions to maintain tolerances, then transported to site.

Fitment on site requires lifting heavy pre‑fabricated beams, aligning them precisely, making final bolt/weld connections and then applying coatings or treatment. Build Matt coordinates transport logistics, temporary supports and ensures that beam ends, bearing conditions and interface surfaces meet requirements.

For metro flyovers or elevated expressways, factors like traffic interruptions, safety, noise and aesthetics influence design of steel structures. Build Matt ensures that steel structures for urban transport are designed such that site assembly is smooth, minimizing time on site through prefabrication and modularity.

Why Fabrication of Bridge Girders and Flyover Assemblies are Processed by Build Matt?

Build Matt’s process for bridge girder detailing involves:

- Shop drawings: Accurate drawings that show every dimension, welding detail, bolt pattern, splice, camber etc.

- Load simulation: Using finite element analysis or other analytical tools to simulate loads – vehicle loads, dynamic effects, wind, etc. – to ensure girder, splice, web and flange design is adequate under all conditions.

- Cambering: Pre‑cambering is often provided so that when girders are loaded, deflections bring them into flat or desired shape. Proper cambering requires predicting load‑deflection curves, controlling fabrication tolerances and verifying after load tests.

- Surface treatment: After fabrication, surfaces may be treated for corrosion protection (galvanizing, painting) or for weather exposure. Welded joints may require grinding or finishing.

- Quality assurance / QA protocols: Inspection of raw materials (certificates of steel grade, test reports), weld inspection (visual, radiography, ultrasonic or magnetic particle as required), dimensional checks, straightness, flatness. Build Matt may adhere to codes or standards

These steps ensure that the steel bridge components and fabricated flyover structures delivered by Build Matt reliably support transportation networks, reducing maintenance, improving safety and ensuring longevity.

What is the Role in Delivering Tower Structures for Critical Infrastructure?

Tower fabrication involves segmental modules for efficient transport and assembly. Build Matt fabricates cross arms, leg sections, bracing, gussets and connecting elements. Wind‑load and seismic load calculations guide design of shapes and wall thicknesses, especially for tubular and angular members. The steel tower fabrication process includes forming, rolling (if tubular), cutting, welding, drilling holes for bolt connections and galvanizing external surfaces.

Some tower types like telecom monopoles are tubular and require precise forming, welding and finishing. Larger lattice towers need many bracing members and connections – bolt hole accuracy is essential so that field assembly is correct. Modular steel towers may be dispatched in segments that fit into trucks or containers with minimal waste or transport constraints.

Precision in these towers ensures reliability: misaligned cross arms or bracing can lead to wind‑induced vibrations or fatigue failure. Build Matt’s approach includes trial assembly in the shop to verify fit‑up, testing of welds and final checks before dispatch.

Why Pre Cambered Bridge Girders Ensure Load Precision?

Pre‑cambered girders are those that have been fabricated with a slight upward curvature so that under dead load and live load they deflect to a nearly flat profile, reducing service camber distortion. Build Matt engineers design camber using load‐deflection curves, material properties, span length and expected load profiles.

The process involves:

- Determining required camber geometry based on service loads, using structural analysis.

- Ensuring fabrication tolerance so the camber is accurately introduced – for example, in flanges or through temporary jigs.

- Welding sequence and pre‑stress or internal stresses managed so that camber is not lost by heat or distortion.

- Dimensional tolerance checks after fabrication to confirm camber, straightness, twist and alignment.

This ensures that highway bridge beams, built‑up girder manufacturing and heavy steel girders perform as expected in service, reducing sagging, misalignment and uneven load distribution.

How Build Matt Ensures Zero Error in Tower and Bridge Steel Fabrication?

Trial fitment or trial assembly in the shop ensures that all parts – girders, beams, tower legs – fit precisely. Bolt hole alignment, splice plate mating, welding clearances are checked. Weld quality control is enforced via visual inspection, non‑destructive testing as required; heat distortion is mitigated by proper sequencing and pre‑weld stiffeners.

Transport‑friendly design is also considered, segments are sized to be carried by available road or rail or modular dispatch; joints are designed so that field assembly is minimal. All of this contributes to minimal error, efficient erection and reduced on‑site rework.

Conclusion

Build Matt functions at the cutting edge of structural steel fabrication, handling bridges, towers, girders and flyovers with the precision, strength and quality engineering that infrastructure demands. Through rigorous detailing, high‑strength component manufacturing, camber control, advanced modelling tools (such as Tekla), trial assembly and stringent QA/QC protocols, Build Matt delivers steel structures that serve as the backbone of modern transportation, utility and communications networks. As Uganda continues to expand its infrastructure – metros, highways, railways, telecom – builders like Build Matt play a vital role in ensuring the bridges we cross, the towers that transmit and the flyovers that elevate our cities are engineered to last.

FAQs About Steel Fabrication for Bridges, Towers, Girders, & Flyovers

Build Matt manufactures various types of girders like deep welded I-beams, built-up box girders, welded plate girders and pre-cambered girders. These are used in both road and railway bridges to handle heavy loads and long spans.

Build Matt ensures precision by using detailed shop drawings, advanced load simulations, strict quality checks, certified welding methods and trial assemblies before final dispatch. They follow strict engineering and safety standards.

Yes, Build Matt handles the complete fabrication of urban flyovers, highway flyovers and also builds telecom towers, power transmission towers and monopoles using strong steel and corrosion protection methods.

Cambering means adding a slight upward curve to steel girders during fabrication. It helps the girder stay level when heavy loads are applied later, preventing sagging and ensuring a longer-lasting structure.

Build Matt fabricates lattice towers, tubular and angular towers, monopoles and segmental tower sections. These are used for telecom and power transmission and are designed to withstand strong winds, weather and long-term usage.

Founder & CEO

Mukesh Patel is the Founder & CEO of Build Matt ltd, specializing in Pre-Engineered Buildings (PEB) and general steel fabrication. With advanced technology, modern machinery, and a skilled workforce, he delivers efficient and high-quality solutions across East and Central Africa, including Uganda, Kenya, Tanzania, Congo, South Sudan, Rwanda, and Burundi.

- Steel Walkways Usage in Suspended Bridge and Overhead Platforms

- Steel Walkways Usage in Suspended Bridge and Overhead Platforms

- Steel Walkways by Build Matt Engineering the Path to Safety

- Roof Ventilation: Everything Homeowners Need to Know

- Steel Mezzanine Floors in Uganda: Comprehensive Guide by Build Matt Ltd