How Steel Agricultural Buildings Offer Long-Term Solutions?

Steel Agricultural Buildings for Storage and Farm Operations

Farming operations involve complex storage, housing and operational requirements that fluctuate with seasonal cycles, climatic conditions and resource availability. Agricultural Storage Buildings and Prefabricated Agricultural Buildings are structured environments designed to accommodate these needs in a consistent, controlled manner.

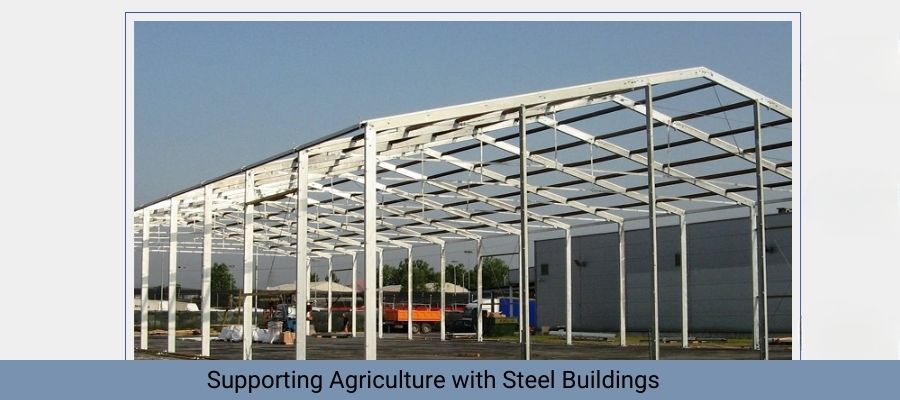

Steel Agricultural Buildings are constructed from pre-engineered steel components, configured to support heavy loads, spatial requirements and environmental controls. The pre-fabrication process allows for precise construction, ensuring structural stability and uniformity. Understanding these structures provides insight into how farms can organize storage, optimize space and maintain operational consistency.

What Constitutes a Pre-Engineered Agricultural Building?

A Pre-engineered Agricultural Building consists of modular steel frames, roof trusses, wall panels and support columns designed for specific load-bearing and spatial requirements. The design process involves:

- Structural Analysis: Determining the load requirements based on intended use, such as equipment storage or grain silos.

- Material Specification: Selection of steel grades, panel thickness and fasteners to meet durability and rigidity needs.

- Component Fabrication: Off-site manufacturing of frames, panels and trusses for precise tolerances.

- Assembly Planning: Layout planning for columns, beams and roofing to ensure alignment, balance and structural integrity.

These buildings may incorporate additional features, such as reinforced floors, ventilation systems or partitioned spaces, depending on operational requirements. Each component is engineered to fit together with minimal modification, ensuring functional accuracy during assembly.

How Steel Structures Support Agricultural Operations

Steel agricultural buildings are designed to accommodate multiple operational scenarios. These include:

- Storage Organization: Structures can be segmented into zones for grains, fertilizers or equipment.

- Environmental Management: Ventilation systems, adjustable openings and insulated panels regulate airflow and interior conditions.

- Spatial Optimization: Modular layouts allow for systematic arrangement of machinery, feed and storage containers.

- Load-Bearing Capacity: Engineered frames provide support for heavy machinery or stacked storage units without compromising structural integrity.

The design of these buildings reflects the technical requirements of farm operations, ensuring that storage, housing and equipment needs are systematically addressed.

What Are Prefabricated Farm Sheds?

Prefabricated Farm Sheds are a subset of pre-engineered agricultural buildings designed for rapid assembly and modular configuration. They consist of prefabricated standardized steel frames, roofing panels and wall assemblies. Prefabrication allows for:

- Precise Component Integration: Each element is manufactured to exact dimensions to fit together without modification.

- On-Site Assembly Planning: Components are assembled following engineered drawings to maintain structural alignment and load distribution.

- Functional Zoning: Internal spaces can be designated for equipment, feed storage or temporary livestock housing.

Prefabricated sheds provide a controlled environment where operational tasks can be carried out efficiently, as the internal layout can be tailored to functional workflows.

What Technical Considerations Are Involved in Agricultural Steel Buildings?

The design and construction of Steel Agricultural Buildings require careful attention to multiple technical aspects:

- Structural Load Assessment: Engineers calculate dead loads (weight of the building materials) and live loads (stored materials, machinery) to determine frame specifications.

- Wind and Snow Loads: Structures are designed to maintain integrity under regional wind pressures and snow accumulation patterns.

- Material Selection: Steel grade, corrosion resistance and fastener strength are selected according to environmental exposure.

- Foundation Engineering: Concrete foundations or anchor systems are designed to distribute loads evenly and prevent subsidence.

- Thermal Expansion: Structural design accounts for steel expansion and contraction under temperature variations to prevent deformation or joint stress.

These considerations ensure that Agricultural Storage Units function as intended throughout varying operational and environmental conditions.

How Are Steel Agricultural Buildings Constructed?

The construction process involves several systematic steps:

- Site Preparation: Land leveling, foundation layout and drainage planning are completed before assembly.

- Frame Assembly: Columns and trusses are erected according to design specifications, ensuring vertical alignment and structural stability.

- Roof and Wall Installation: Prefabricated panels are mounted, ensuring secure fasteners and proper sealing at joints.

- Internal Structuring: Partitioning, shelving and ventilation systems are integrated as per operational requirements.

- Inspection and Testing: Structural joints, load distribution and alignment are verified before the building is commissioned for use.

Each step is guided by engineering standards to ensure the building can sustain intended operational loads and environmental conditions.

What Functional Features Are Common in Agricultural Storage Structures?

Steel farm structures incorporate functional features designed to support operational tasks:

- Segmentation: Dividing internal space into zones for different types of storage or operations.

- Ventilation and Airflow Control: Adjustable openings and vents allow for air circulation, minimizing moisture accumulation.

- Floor Load Distribution: Reinforced flooring accommodates machinery or heavy storage units without compromising stability.

- Modular Extensions: Buildings can be expanded by adding additional steel frames or panels as operational needs evolve.

These features facilitate organized workflows, spatial optimization and structural reliability.

How Do Prefabricated Buildings Fit into Farm Operational Planning?

Prefabricated structures allow farm operators to plan storage and operational workflows systematically. Spatial planning may involve:

- Assigning storage zones based on type or hazard classification of materials.

- Designing access routes for machinery and personnel to maintain operational efficiency.

- Allocating areas for temporary or seasonal storage, adapting to crop cycles or livestock rotations.

- Integrating utility systems such as water, ventilation and electrical distribution to support operational processes.

By integrating structural and operational planning, Agricultural Steel Buildings function as integral components of farm management.

Conclusion: The Functional Role of Steel Agricultural Buildings

FAQs About Pre-Engineered Agriculture Buildings

They are modular steel structures designed with engineered frames, panels and foundations to meet specific farm operational requirements.

Construction involves site preparation, frame assembly, panel installation, internal structuring and inspection to ensure functional accuracy.

Segmentation, ventilation, reinforced flooring and modular extensions are common features supporting functional workflows.

Yes, internal layouts, dimensions, ventilation and access points can be tailored to operational needs.

They support spatial planning, workflow organization and utility integration to maintain consistent agricultural operations.

Founder & CEO

Mukesh Patel is the Founder & CEO of Build Matt ltd, specializing in Pre-Engineered Buildings (PEB) and general steel fabrication. With advanced technology, modern machinery, and a skilled workforce, he delivers efficient and high-quality solutions across East and Central Africa, including Uganda, Kenya, Tanzania, Congo, South Sudan, Rwanda, and Burundi.

- Steel Walkways Usage in Suspended Bridge and Overhead Platforms

- Steel Walkways Usage in Suspended Bridge and Overhead Platforms

- Steel Walkways by Build Matt Engineering the Path to Safety

- Roof Ventilation: Everything Homeowners Need to Know

- Steel Mezzanine Floors in Uganda: Comprehensive Guide by Build Matt Ltd