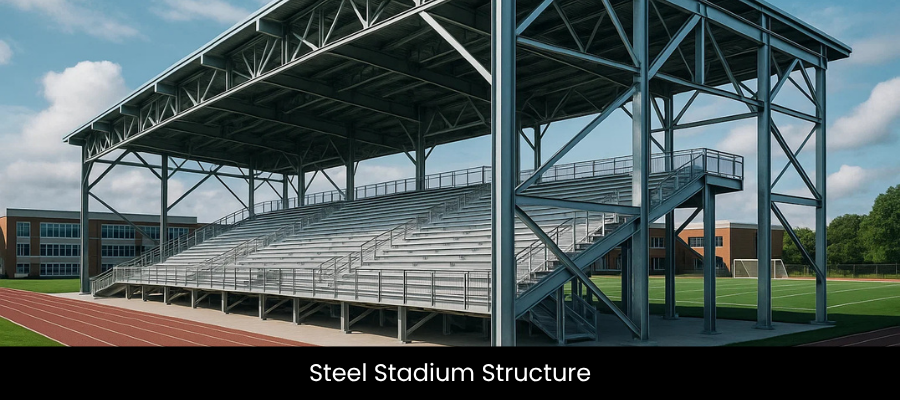

How Steel Stadium Structures Enhance School Sports Infrastructure: A Step-by-Step Guide

Step 1: Understanding the Concept of Steel Stadium Structures

Advantages:

- Steel is durable and resistant to environmental factors.

- Prefabrication ensures quick assembly, reducing project timelines.

- Can be customized to fit specific design needs and capacities.

In a school setting, these structures are tailored to provide reliable sports facilities without exceeding budget limits.

Step 2: Planning the Design and Layout of the Steel Stadium

Key Considerations in Design:

- Seating Capacity: Depending on the size of the school and its sports programs, the number of seats must be determined. Steel structures can easily accommodate large crowds.

- Field Dimensions: The sports field needs to be designed according to the type of games that will be played, such as football, soccer or athletics.

- Accessibility: Adequate ramps, entrances and seating for those with disabilities are incorporated into the design.

- Safety Features: With steel, safety can be ensured through reinforced structures that can withstand pressure from large crowds and adverse weather.

Step 3: Prefabrication and Manufacturing of Steel Components

Benefits of Prefabrication:

- Quality Control: Steel components are fabricated in a controlled environment, ensuring high-quality standards are maintained.

- Time Efficiency: Since the components are ready for assembly once they arrive at the site, this significantly reduces construction timelines.

- Reduced On-Site Labor Costs: With prefabrication, fewer laborers are needed on-site, reducing overall construction costs.

Steel components are manufactured according to precise measurements and specifications, ready to be transported for quick assembly.

Step 4: Site Preparation and Steel Structure Foundation Work

Key Tasks in Site Preparation:

- Clearing and Excavation: The site must be prepared for construction, including the removal of debris, rocks and other obstacles.

- Foundation Design: The foundation is designed to handle the weight of the structure and any potential stresses caused by sports events or large crowds.

- Utility Installation: Essential utilities such as electricity, water and drainage systems must be set up to support the stadium.

Step 5: Erecting the Steel Stadium Structure

Steps in Erection:

- Framework Installation: The main steel frame, including columns, beams and trusses, is erected to form the skeleton of the stadium.

- Roof and Cladding: The roof structure and external cladding are installed, ensuring the stadium is weatherproof and protected from the elements.

- Seating and Amenities: Seating areas are built and any amenities such as concessions, restrooms and lockers are added to enhance the user experience.

Step 6: Finishing Touches and Customization of Sports Stadium

Customization Options:

- Lighting and Sound Systems: Steel structures can support large-scale lighting and sound installations to ensure visibility and an enhanced spectator experience during night games.

- Architectural Features: Steel allows for creative designs in the facade and other architectural elements, providing a modern, sleek appearance.

- Sports Equipment and Fields: Depending on the type of sports events the stadium will host, fields for football, track and field or soccer can be installed with steel support for barriers, nets and other structures.

Step 7: Ongoing Maintenance of Sports Stadium and Longevity

Maintenance Tasks:

- Rust Prevention: Though steel is resistant to corrosion, regular painting and coating can further enhance its longevity.

- Structural Inspections: Routine checks of the frame, roof and foundation are necessary to detect any potential issues before they become significant problems.

- Safety Checks: Ensuring that seating, access points and emergency exits are in good condition is vital for maintaining safety standards.

Conclusion

Steel stadium structures are a game-changer in school sports infrastructure development. Their combination of durability, cost-efficiency, rapid construction and aesthetic flexibility makes them an ideal choice for modern schools looking to enhance their sports facilities. By following the steps outlined above, schools can build state-of-the-art sports stadiums that provide a safe, efficient and enjoyable experience for athletes and spectators alike.

FAQs

Steel stadium structures offer numerous advantages, including durability, cost-effectiveness, quick construction time and minimal maintenance. Steel’s ability to withstand harsh weather conditions and heavy usage makes it an ideal choice for school sports facilities.

The construction time for a steel stadium is significantly shorter than traditional methods. Prefabricated steel components are assembled on-site, reducing the overall project duration. Depending on the complexity and size of the stadium, the project can take as little as a few months.

Yes, steel stadiums are highly customizable. Whether the facility needs to accommodate a football field, an athletic track or other sports, steel structures can be adapted to meet the specific requirements of the sporting events held at the school.

Steel stadiums enhance safety by offering a strong and stable framework that can withstand the stress of large crowds and physical activities. Steel is fire-resistant and provides a high level of protection against natural disasters like earthquakes and heavy winds.

Steel stadiums require minimal maintenance, but regular inspections and upkeep are necessary. Tasks include rust prevention, structural inspections and ensuring that safety features like seating and exits are in optimal condition.

Founder & CEO

Mukesh Patel is the Founder & CEO of Build Matt ltd, specializing in Pre-Engineered Buildings (PEB) and general steel fabrication. With advanced technology, modern machinery, and a skilled workforce, he delivers efficient and high-quality solutions across East and Central Africa, including Uganda, Kenya, Tanzania, Congo, South Sudan, Rwanda, and Burundi.

- Steel Walkways Usage in Suspended Bridge and Overhead Platforms

- Steel Walkways Usage in Suspended Bridge and Overhead Platforms

- Steel Walkways by Build Matt Engineering the Path to Safety

- Roof Ventilation: Everything Homeowners Need to Know

- Steel Mezzanine Floors in Uganda: Comprehensive Guide by Build Matt Ltd