Founder & CEO

Mukesh Patel is the Founder & CEO of Build Matt ltd, specializing in Pre-Engineered Buildings (PEB) and general steel fabrication. With advanced technology, modern machinery, and a skilled workforce, he delivers efficient and high-quality solutions across East and Central Africa, including Uganda, Kenya, Tanzania, Congo, South Sudan, Rwanda, and Burundi.

Recent Blogs

- Steel Kiosk Manufacturing Key Differences in Mall, Banking, and Parking Applications

- Prefabricated Poultry Farm in Uganda: Step-by-Step Building Guide

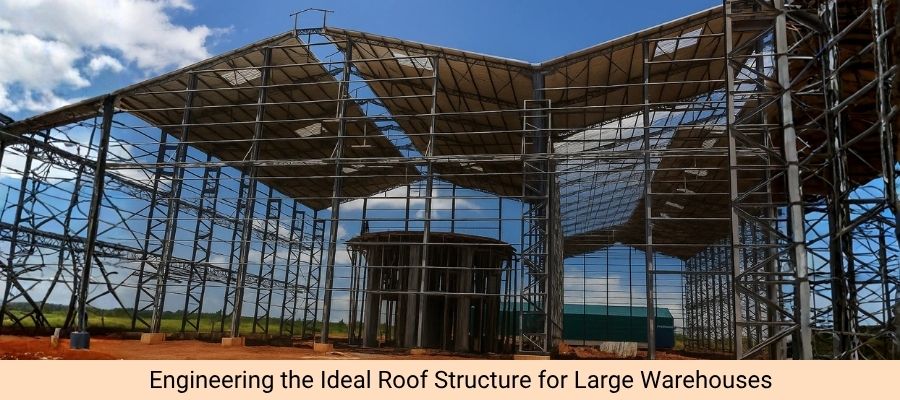

- How Modern Warehousing Contractors Integrate Steel Structures with Digital Design in Uganda

- Steel Mezzanine Floor & Roof Structure Engineering for Large Warehouses by Contractors in Uganda

- The Growing Demand for Prefabricated Walkways in Uganda’s Various Industries